A Deep Dive into Wire Bonding Machines and Equipment

Introduction

In the quick-paced world of electronics manufacturing, the significance of robust interconnection recommendations is not going to be overstated. Among those, cord bonding emerges as a cornerstone expertise. This article ambitions to grant a finished analysis of twine bonding machines and appliance, delving into quite a number points including tactics, applied sciences, ideas, applications, and destiny trends within the enterprise. Understanding twine bonding is vital for engineers and manufacturers alike in attaining reliability and fine in electronic gadgets.

What is Wire Bonding?

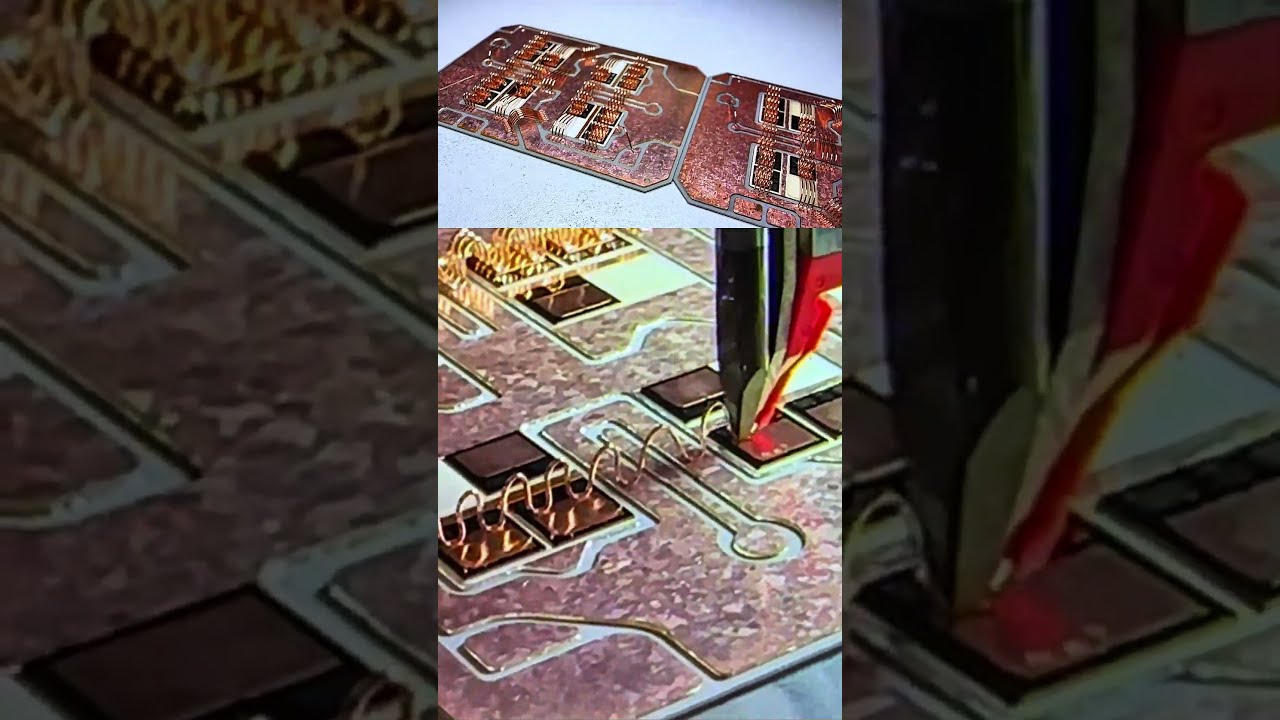

Wire bonding is a style used to create electric connections between semiconductor chips and their programs or substrates. It comes to with the aid of advantageous wires—mostly constituted of gold, aluminum, copper, or silver—to establish those connections. The method might possibly be performed using assorted ways which include ball bonding, wedge bonding, and ribbon bonding.

The Wire Bonding Process

The cord bonding job quite often carries various key steps:

This problematic job guarantees official connections which can be fundamental for the functionality of digital devices.

Types of Wire Bonding Techniques

Wire bonding era has advanced over the years, ensuing in a number of ways perfect for distinctive applications:

Ball Bonding

Ball bonding is among the many most regularly occurring techniques, typically through gold or copper wires. In this approach:

- A ball is shaped on the cease of the twine the use of warmness.

- The ball is then pressed onto the bond pad to shape a connection.

Wedge Bonding

Wedge bonding employs a flat tool rather then a ball to make contact with both surfaces. This methodology is rather a good option for:

- Aluminum wires

- Applications requiring scale back temperatures

Ribbon Bonding

Ribbon bonding makes use of flat ribbons rather than round wires, bearing in mind top present capacities and diminished inductance. It's primarily utilized in vigor modules and high-frequency packages.

Wire Bonding Machines: An Overview

What Are Wire Bonding Machines?

Wire bonding machines are really expert accessories designed to automate the wire bonding activity. They are available in alternative varieties such as manual, semi-automatic, and entirely computerized machines.

Features of Modern Wire Bonding Equipment

Modern wire bonding platforms be offering loads of capabilities aimed at expanding performance and ensuring first-class bonds:

- Programmable settings

- Advanced monitoring systems

- Automated inspection tools

These qualities guide streamline construction while declaring stringent pleasant management concepts.

How Wire Bonding Works: A Technical Insight

Understanding how cord bonding works contains greedy both mechanical and thermal features:

Bond Strength in Wire Bonding

Bond force is critical for reliability in electronic gadgets; it would be prompted through aspects inclusive of:

- Material option (gold vs aluminum)

- Environmental conditions

- Process parameters (temperature and force)

Measuring bond electricity frequently entails pull exams or shear assessments designed to judge the integrity of connections.

Wire Bonding Applications Across Industries

Wire bonding reveals its utility throughout assorted sectors resulting from its adaptability:

1. Wire Bonding in Semiconductors

The semiconductor industry relies heavily on cord bonding for connecting incorporated circuits (ICs) to applications or substrates effortlessly.

2. Wire Bonding for Medical Devices

Medical units require prime-reliability connections; therefore many make the most of stepped forward cord bonding tactics like tremendous pitch ball bonding.

three. Automotive Electronics Wire Bonding

As automobiles turn into extra complicated with electronics, nontoxic interconnections with the aid of cord bonds are important for safeguard platforms and infotainment positive factors.

The Economics of Wire Bonding: Cost Considerations

Understanding the expense implications associated with various cord bonding processes can assistance manufacturers optimize their operations:

1. Initial Investment vs Long-term Costs

While automatic machines have a larger upfront rate, they as a rule bring about diminish exertions bills over time simply by elevated throughput.

2. Material Costs: Gold vs Aluminum vs Copper Wires

Gold wires are greater costly than aluminum however present choicest overall performance underneath bound prerequisites (e.g., top-frequency functions).

Quality Control in Wire Bonding Processes

Ensuring nice for the duration of production techniques can steer clear Extra resources of defects that end in failure modes later on:

1. Visual Inspection Techniques

Visual inspection is still one of the most so much undemanding tricks for choosing expertise concerns early on which includes bond carry-off or heel cracks.

2. Non-unfavourable Testing Methods

Techniques comparable to x-ray inspection or computerized optical inspection (AOI) permit producers to assess bond integrity with out adverse ingredients.

Wire Bond Failure Analysis: Understanding Defects

Fail-trustworthy design calls for understanding how failures appear inside of bonded constructions:

Common Types of Wire Bond Failures

| Failure Mode | Description | |---------------------|-----------------------------------------------| | Heel Cracks | Cracks at the base of the bond | | Lift-Off | Complete detachment from bond pad | | Oxidation | Deterioration via environmental exposure |

Understanding these failure modes enables tell more beneficial layout practices and upkeep schedules.

FAQs

1. What ingredients are almost always used for twine bonds?

Gold, aluminum, copper, and silver are normal substances used for cord bonds with the aid of their conductive houses.

2. How does temperature impression the cord bonding job?

Temperature performs a full-size function; upper temperatures can enhance bond potential however also can end in drapery degradation if now not controlled accurate.

3. What industries predominantly use wire bonding science?

Industries comprise semiconductors, car electronics, medical gadgets, aerospace engineering, telecommunications, and so on.

four. How can I learn more about wire bonding concepts?

Numerous supplies exist online which includes tutorials reachable in PDF structure or instructional videos that deliver visual demonstrations of procedures interested in wire binding.

5. What are a few time-honored challenges confronted throughout the time of wiring tactics?

Challenges embrace coping with thermal expansion distinctions among elements used or combating oxidation earlier than making connections which might compromise integrity.

Conclusion

In end, understanding "A Deep Dive into Wire Bonding Machines and Equipment" unearths its mandatory function throughout varied industries—from semiconductors to automotive electronics—the place legit interconnections style the spine of fashionable expertise progress efforts right now! By studying either standard approaches like ball/wedge/ribbon tactics inclusive of new improvements emerging from improvements inside of Industry 4.zero frameworks—manufacturers stand poised no longer just purely survive but thrive amidst ever-growing competitors panorama beforehand!

With knowledge won across this exploration—even if you are an engineer searching for real looking insights into imposing robust procedures inside your possess operations—or honestly curious approximately contemporary trends shaping long run landscapes—bear in mind that thorough comprehension leads sooner or later in direction of more desirable productiveness & fulfillment inside any field involving elaborate digital platforms!