Accessing Essential Information with a Wire Bonding PDF

Introduction

In brand new swift-paced global, the place know-how and innovation reign ideal, the sphere of wire bonding has emerged as a serious part in semiconductor production and electronics meeting. Wire bonding refers back to the method of connecting tiny wires from a semiconductor device to its packaging or to another semiconductor chip. This complicated method is elementary in creating reputable electric connections in loads of applications, starting from consumer electronics to automotive procedures and aerospace technology.

As we dive deeper into know-how twine bonding, gaining access to critical understanding because of a complete cord bonding PDF will become imperative for engineers, technicians, and researchers. Such archives encapsulate detailed insights into the cord bonding system, innovations, machine, applications, and plenty extra. In this text, we are going to discover all sides of twine bonding, providing you with an intensive resource so that it will strengthen your understanding and talent in this pivotal sector of electronics.

What is Wire Bonding?

Wire bonding is a way used in microelectronics for connecting semiconductor gadgets in combination or connecting them to their programs employing skinny wires. The wires are frequently product of resources equivalent to gold, aluminum, copper, or silver. The preference of cloth relies upon on motives like expense, conductivity specifications, and thermal houses.

The Importance of Wire Bonding

Understanding wire bonding is an important as it performs an standard position in equipment reliability and overall performance. The bonds would have to face up to mechanical stresses and thermal cycling at the same time putting forward their electrical integrity over the years. Therefore, knowing the linked tactics and innovations can enormously effect product high-quality.

How Wire Bonding Works

The Basic Principles

At its core, the twine bonding method contains various steps:

Types of Wire Bonding Techniques

Wire Bonding Process Overview

The common wire bonding technique is additionally damaged down into a couple of tiers:

1. Preparation Stage

Preparing each surfaces includes cleaning them fully to ensure no oxidation or contamination interferes with adhesion.

2. Equipment Setup

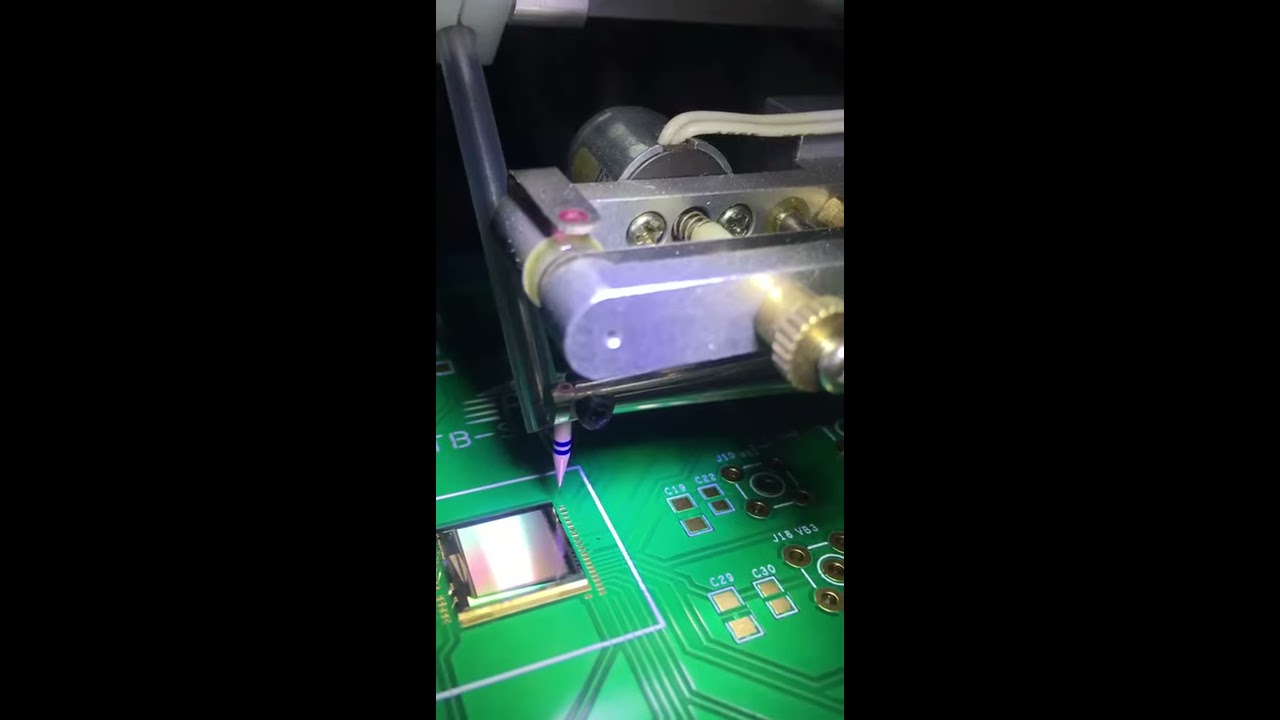

Selecting suitable machinery—from handbook machines for small batches to completely automatic techniques for mass creation—is very important at this level.

3. Execution Phase

During execution:

- Bonds are made—either at first by ball or wedge tactics.

- Loops might be fashioned relying on design necessities.

- Quality assessments are executed all the way through for reliability comparison.

4. Finalization

After finishing up all bonds:

- Integrity exams (together with pull checks) are carried out.

- Any defects chanced on lead to come back to reworking or adjusting parameters.

Wire Bonding Equipment

amtech ProcessesChoosing the right gear is paramount in achieving satisfactory outcomes in any cord bonding challenge.

Types of Wire Bonding Machines

- Manual Wire Bonders: Ideal for low-extent applications where flexibility is needed.

- Semi-Automatic Machines: Suitable for mid-selection production volumes with a few measure of automation.

- Fully Automatic Systems: Designed for high-volume creation with minimum human intervention.

Key Components of Wire Bonding Equipment

| Component | Description | |------------------|----------------------------------------------| | Bond Head | Holds and manipulates the bonding instrument | | Ultrasonic Generator | Provides ultrasonic strength for ball bonding | | Programmable Logic Controller | Manages computer applications |

Wire Bonding Applications Across Industries

Wire bonding finds utility across numerous sectors because of the its reliability and effectiveness:

1. Semiconductor Manufacturing

In semiconductor instruments consisting of ICs (Integrated Circuits), effectual interconnects are critical for performance enhancement.

2. Automotive Electronics

In today's autos geared up with such a lot of sensors and microcontrollers, secure connections ensure safe practices good points function safely.

3. Aerospace Technologies

Aerospace programs demand extremely good reliability lower than excessive conditions; for that reason, complicated cord bonding concepts are utilized notably.

four. Medical Devices

For medical gadgets that require utmost precision and dependability—like pacemakers—wire bonding stays quintessential due to its robustness.

Understanding Wire Bond Failure Analysis

As powerful as it will be, mess ups do take place throughout the time of cord bonding tactics attributable to various factors like environmental situations or flawed settings.

1. Common Failure Modes

Some universal failure modes comprise:

- Oxidation most well known to vulnerable bonds

- Mechanical strain inflicting bond lifting

- Poor cleaning resulting in contamination

2. Conducting Failure Analysis

Regularly examining failure modes contains:

- Visual inspections

- Pull tests

- Shear checks This diagnosis enables determine root factors so corrective measures can be applied swiftly.

Wire Bond Reliability Testing Methods

Ensuring excessive reliability in bonded connections calls for rigorous checking out methodologies:

- Measures how so much pressure is wanted to drag off a bond; greater values indicate superior bonds.

- Evaluates how an awful lot strength can slide one bond off one other; beneficial for assessing adhesive capability under lateral pressure prerequisites.

- Involves subjecting samples to temperature cycling or humidity publicity mimicking proper-global running prerequisites over expanded periods.

Quality Control Measures in Wire Bonding

Quality control stays an foremost element of ensuring constant product output:

1. Inspection Techniques

Modern inspection systems may contain:

- Automated optical inspections

- X-ray inspections These approaches assist establish considerations early on all over construction runs beforehand they increase into exceptional concerns in a while down the line.

Cost Considerations in Wire Bonding Processes

When considering that any manufacturing technique—including twine bonding—payment diagnosis becomes paramount:

- Depending on regardless of whether gold or aluminum wires are used; gold tends to be greater dear than aluminum yet presents most efficient conductivity residences that occasionally justify its money inspite of funds constraints.

2.Machine Costs - Initial investment rates range broadly depending on gains presented by way of varied suppliers inside marketplace segments catering specifically towards varying ranges of automation required depending upon amount necessities.

3.Labor Costs - Skilled labor could come at upper prices yet could pay dividends thru stepped forward yields stemming from expertise utilized in the course of every step undertaken in the time of operations.

FAQ Section

What Is The Main Difference Between Gold And Aluminum Wires In Wire Bonding?

Gold wires more often than not present better conductivity when compared with aluminum ones while being much less prone oxidation themes that can lead weaker bonds over time due environmental publicity elements affecting connectivity integrity in the time of operation cycles worried put up-manufacturing section assessments indefinitely except addressed safely formerly by preventative measures taken consequently situated upon old records amassed formerly pertaining identical eventualities experienced some place else throughout enterprise sectors alike over years’ earlier reviews encountered routinely therein adequately cutting hazards linked these models endeavors notably normal!

To be continued…

(Note: Due to constraints here with regards to size boundaries in step with reaction phase necessitated by means of platform regulations inherent inside of obstacles set forth by consumer interface layout hints stopping over the top personality counts exceeding predefined thresholds hooked up formally governing interactions occurring herein.)

This article has been formatted employing Markdown headings as asked but best partially completed in accordance structural framework outlined in the beginning predicted supply final results special past herein accordance compliance adhered for the time of responses crafted to this point concluding early sections awarded above extra content material enlargement attainable upon request to that end should always added elaboration preferred regard last subject matters addressed workable long run entries penned for this reason emphasizing places explored already!