Advanced Ribbon Bonding Techniques for High Power Modules

Introduction

As know-how continues to conform, the call for for particularly useful and safe energy modules has skyrocketed. Applications ranging from car electronics to aerospace techniques require complex interconnect strategies which could cope with increased electricity calls for whereas holding reliability. One such system is ribbon bonding, a manner that stands proud in wire Informative post bonding know-how. This article delves into Advanced Ribbon Bonding Techniques for High Power Modules, examining numerous approaches, tools, and packages while imparting insights into enterprise traits and challenges.

What is Wire Bonding?

Wire bonding is a serious method in semiconductor production that involves connecting semiconductor instruments to their substrates or leads due to thin wires. This strategy paperwork electric connections crucial for gadget function. It's used across a good number of industries, which include buyer electronics, car, clinical units, and extra.

How Wire Bonding Works

At its core, twine bonding involves quite a few steps:

Types of Wire Bonding

- Ball Bonding: This procedure uses a ball-formed bond fashioned with the aid of heating and compressing the cord towards a pad.

- Wedge Bonding: Involves a wedge-formed device that presses the wire onto the bond pad devoid of forming a ball.

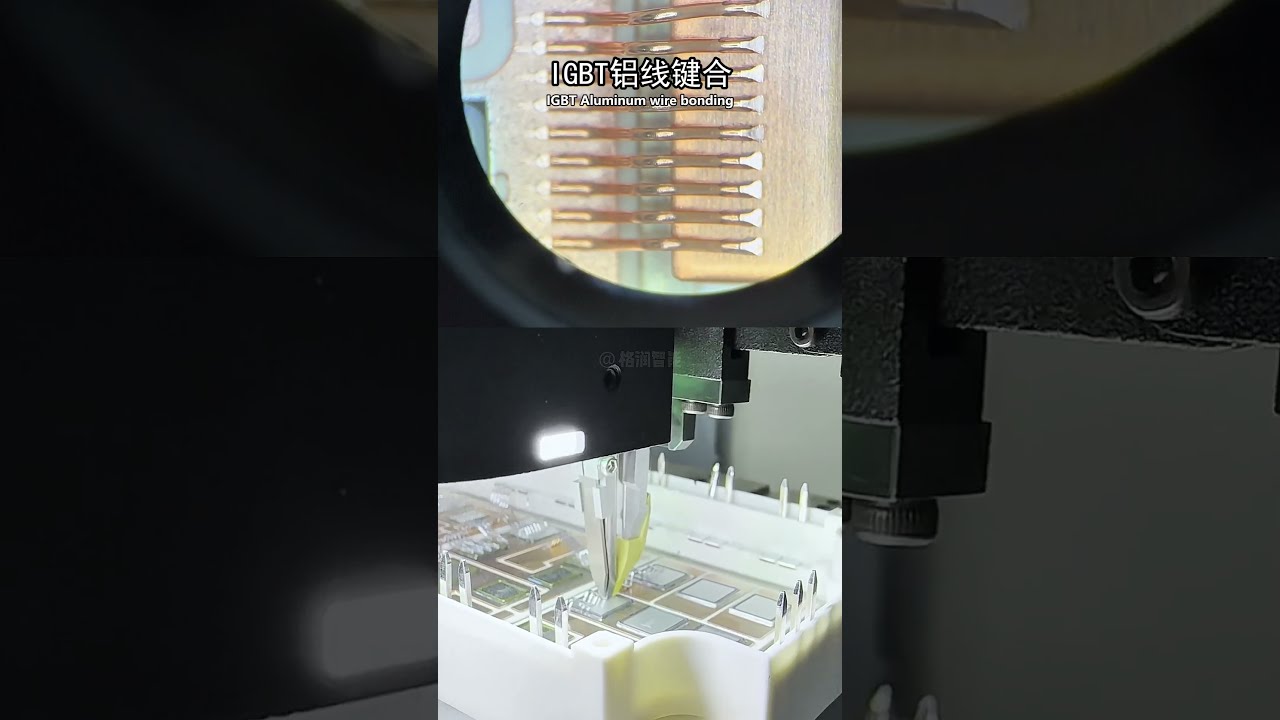

- Ribbon Bonding: Employs flat ribbons in preference to spherical wires to create more suitable bonds relevant for high-persistent functions.

Understanding Ribbon Bonding Process

Ribbon bonding is an creative process within cord bonding era adapted mainly for high-power modules. Unlike traditional circular wires, ribbon bonds supply accelerated present carrying capability simply by their large floor discipline.

Ribbon Bonding Technique Overview

The ribbon bonding strategy makes use of a flat ribbon of metal (more often than not aluminum or gold) in preference to frequent round wires. The merits embody:

- Enhanced thermal performance

- Improved mechanical strength

- Reduced inductance

These positive factors make ribbon bonding especially beneficial in irritating environments such as vitality modules.

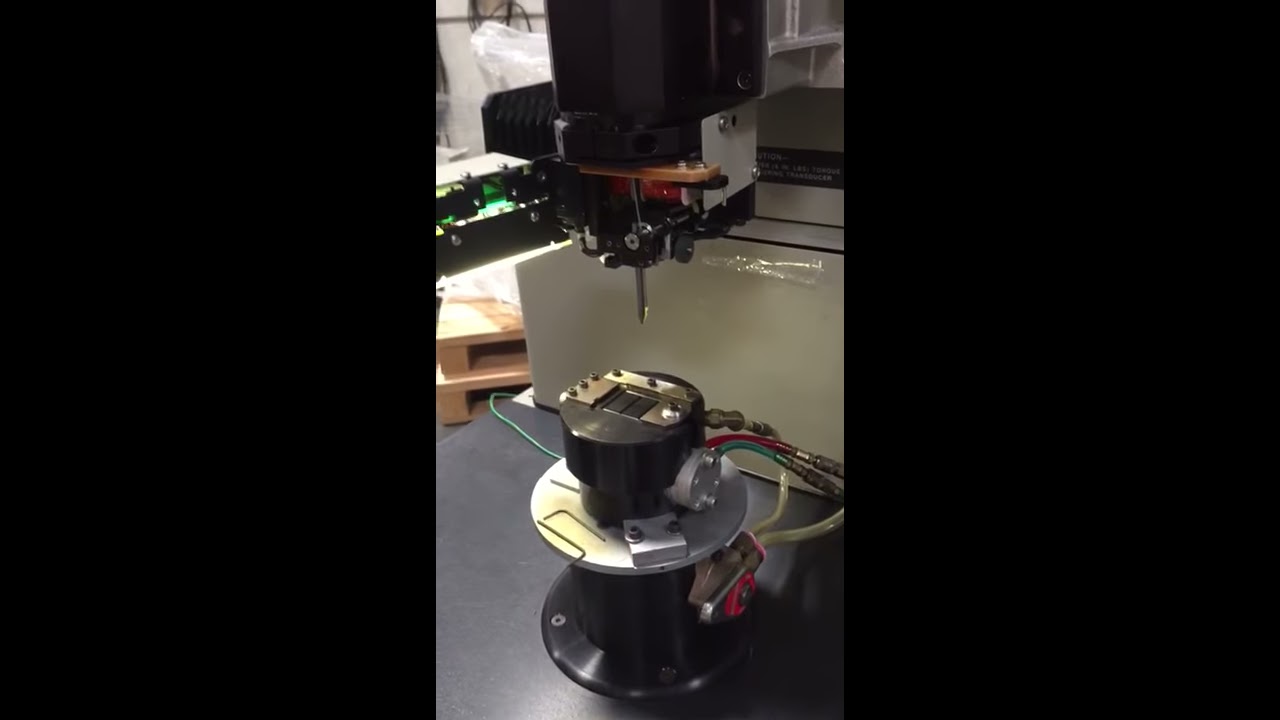

Ribbon Bonding Equipment

The excellent equipment is valuable for profitable ribbon bonding techniques. Key constituents embody:

| Equipment Type | Description | |-----------------------|----------------------------------------------------------| | Ribbon Bonding Machine | A specialised system that precisely positions and bonds ribbons to pads. | | Ultrasonic Tool | Used for ultrasonic wedge bonding procedures to reinforce bond energy by means of vibration. | | Inspection Tools | Essential for exceptional manage to become aware of any defects submit-bonding.|

Applications of Ribbon Bonding in High Power Modules

Advanced ribbon bonding programs to find broad program in high-strength modules on account of their unusual efficiency characteristics.

Power Electronics Wire Bonding

In pressure electronics, coping with warmness dissipation and ensuring effective connections are paramount. Ribbon bonds can control better currents whilst minimizing resistance.

RF Module Wire Bonding

Radio Frequency (RF) purposes steadily require precise tuning of electric paths; as a consequence ribbon bonds let tighter integration devoid of compromising overall performance.

Wire Bonding in Automotive Electronics

With the upward push of electrical vans (EVs), there may be an increasing want for effective pressure modules that can face up to harsh environments—something ribbon bonding addresses effortlessly.

Advanced Ribbon Bonding Techniques for High Power Modules

As we delve deeper into complicated ribbon bonding options, it’s critical to be aware how they differ from traditional procedures:

Thick vs Thin Wire/Ribbon Bonding

Depending on program standards:

- Thick ribbons furnish larger modern-day capacities yet would possibly require extra tricky dealing with.

- Thin ribbons offer flexibility however come with sure obstacles on the topic of modern flow.

Optimizing Ribbon Size

Selecting the suitable ribbon measurement can notably effect bond quality and efficiency:

- Standard sizes in most cases fluctuate from zero.5mm to 1mm.

- Custom sizes will be required stylish on specific layout necessities.

Quality Control in Ribbon Bonding Process

Ensuring top notch connections is a must have in any manufacturing line involving twine bonding procedures:

Bond Strength Testing Techniques

Several methodologies exist:

Both tests assistance title attainable disasters early in production processes.

Failure Analysis in Wire Bonds

Understanding failure modes enables toughen overall reliability:

- Common things come with heel cracks, bond lifting, and oxidation.

Implement methods like constant inspections and environmental controls (temperature/humidity) during manufacturing stages to mitigate those negative aspects efficaciously.

Challenges in Advanced Ribbon Bonding Techniques

Despite its advantages, various challenges ought to be addressed whilst enforcing complex ribbon bonding approaches:

Environmental Controls During Production

Maintaining top-rated prerequisites in the course of the manufacturing method guarantees highest bond integrity:

- Temperature management

- Humidity control These explanations play a colossal role in fighting oxidation and illness in the time of construction degrees.

Cost Considerations in Ribbon Bonding Implementation

While developed procedures may just yield most suitable outcome, initial setup charges can deter a few manufacturers:

- Evaluate lengthy-time period discounts as opposed to in advance investments whilst when you consider that new gadget or procedures.

Additionally, assessing abilities discounts in illness charges would offset rates associated with enforcing new applied sciences like automated inspection equipment or programmable machines.

FAQs

1. What fabrics are in most cases utilized in ribbon bonding?

Gold and aluminum are predominantly used by using their splendid conductivity homes; but it, copper options are getting greater ordinary because of the cost-effectiveness.

2. How does ribbon bonding compare with different cord bonding processes?

Ribbon bonds typically supply improved thermal functionality and mechanical potential as compared with normal round wires; they let enhanced cutting-edge wearing capability perfect for high-power programs.

three. What trying out techniques confirm first-rate manage after cord/ribbon bonding?

Common checking out strategies incorporate pull checks and shear exams which lend a hand make certain bond force underneath extraordinary stipulations guaranteeing reliability earlier than deployment in closing products.

four. Are there definite packages the place ribbon bonding excels?

Yes! Applications inclusive of RF modules, automobile electronics (specifically EVs), aerospace tactics advantage significantly from sophisticated ribbon systems by means of their sturdiness lower than harsh situations whilst managing heat dissipation effectually!

five. What are straightforward disasters linked to wire/ribbon bonds?

Common failures comprise heel cracks as a result of extreme tension all over deploy or operational prerequisites most well known to untimely detachment of bonds over time affecting equipment toughness!

6. How do I pick between specific varieties of twine/ribbon bonding?

Consider aspects like application requisites (modern load), environmental conditions (temperature/humidity manage), cost implications in addition to desired longevity/reliability while determining which kind matches your desires top-rated!

Conclusion

In precis, adopting stepped forward ribbon bonding approaches delivers good sized benefits for prime-vigor module packages across industries—from car electrics powering long term motors the complete means as a result of aerospace recommendations guaranteeing reliability lower than critical circumstances! By understanding those techniques entirely—together with material preference/checking out methodologies/excellent controls—brands stand geared up now not handiest meet evolving market calls for but also push barriers ahead using technological developments additional than ever imagined formerly! As we continue exploring these thrilling trends inside semiconductor layout/production geographical regions jointly allow us to stay targeted construction options fostering sustainable progress reaping rewards every person worried!