Aluminum Wire Bonding: Methods and Applications

Introduction

Aluminum twine bonding has emerged as a integral job inside the realm of electronics manufacturing, tremendously throughout the semiconductor business. As technological know-how advances, the need for productive, stable tactics of connecting chips to substrates will become ever extra paramount. This article delves Have a peek here into aluminum cord bonding, exploring its ways, applications, blessings, challenges, and long term tendencies. By realizing these points, experts could make expert selections referring to their twine bonding processes and machine.

Aluminum Wire Bonding: Methods and Applications

What is Wire Bonding?

Wire bonding refers to a greatly used interconnect system that creates electric connections between microelectronic gadgets and their substrates. The course of includes with the aid of skinny wires—most often fabricated from gold, aluminum, or copper—to set up those connections. It performs a essential position in semiconductor packaging and is a must have for ensuring that electronic contraptions function successfully.

Understanding the Wire Bonding Process

The cord bonding approach is additionally damaged down into numerous key steps:

Types of Wire Bonding Techniques

When it involves twine bonding thoughts, various strategies stand out:

- Ball Bonding: Utilizes a small ball on the quit of the wire created via heating it; very best for nice-pitch applications.

- Wedge Bonding: Employs a wedge-shaped device to create bonds; relevant for thicker wires.

- Ribbon Bonding: Involves as a result of flat ribbon-like wires for top-density programs.

Each methodology has its interesting blessings depending on task specifications.

Wire Bonding Equipment Overview

Wire Bonding Machines

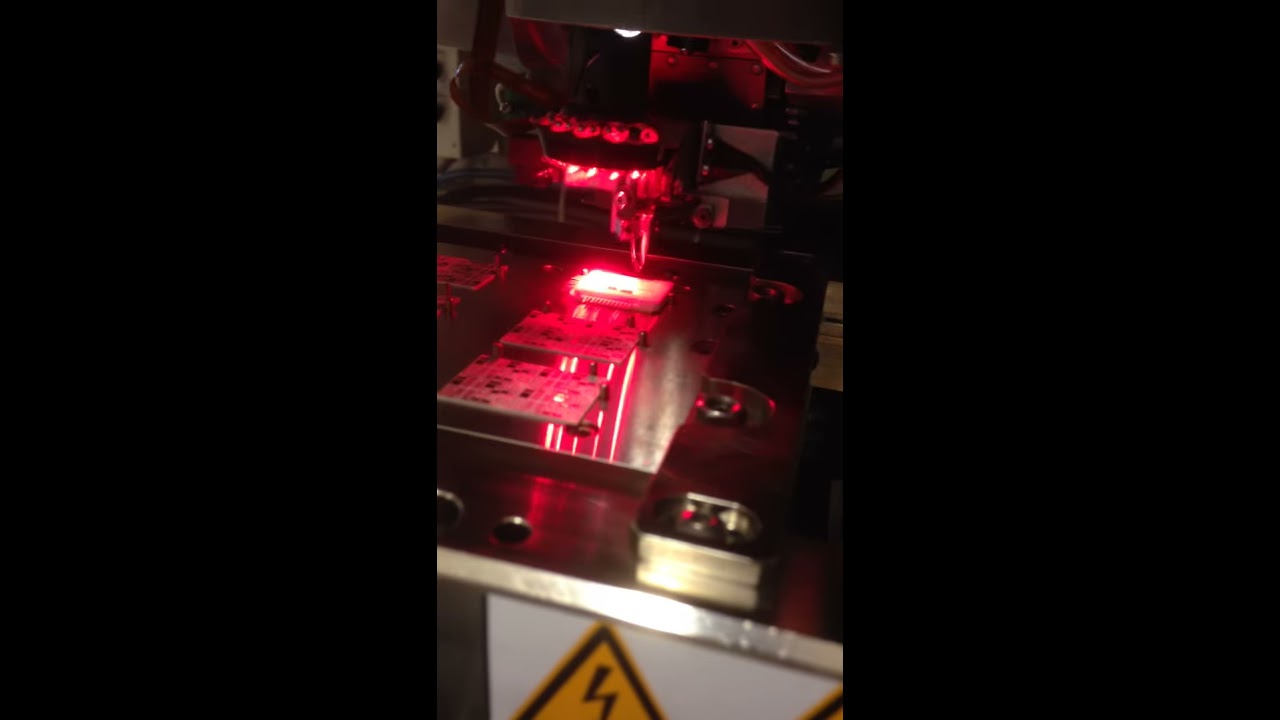

Wire bonding machines are really expert gadget designed to automate the cord bonding manner. Key positive factors most likely embrace programmable settings for special parameters equivalent to temperature and drive.

Manual vs Automatic Wire Bonding Machines

While manual machines give flexibility and control over small batches, automatic machines supply performance for top-amount construction. The decision commonly relies on creation desires.

Applications of Aluminum Wire Bonding in Electronics

Aluminum cord bonding reveals big functions in various sectors:

- Semiconductors: Essential for connecting built-in circuits (ICs) on silicon wafers.

- Automotive Electronics: Used in sensors and management items by means of its reliability less than various circumstances.

- Medical Devices: Critical for making sure durability in lifestyles-saving accessories.

These applications demonstrate aluminum's versatility in assembly today's electronic needs.

Aluminum vs Gold Wire Bonding

When it involves comparing aluminum cord bonding with gold wire bonding:

| Feature | Aluminum Wire Bonding | Gold Wire Bonding | |--------------------------|-----------------------|--------------------| | Cost | Lower | Higher | | Oxidation Resistance | Moderate | Excellent | | Thermal Conductivity | Good | Excellent | | Usage | High extent | Specialty |

Aluminum supplies expense-effectiveness although gold can provide awesome functionality in phrases of oxidation resistance.

Challenges in Aluminum Wire Bonding

Despite its blessings, aluminum twine bonding gives challenges:

Addressing those challenges is essential for putting forward reliability in digital aspects.

Wire Bonding Failure Analysis

Failure analysis in twine bonding contains interpreting defective bonds to identify their root causes—be it infection or flawed handling for the duration of creation.

Wire Bond Reliability Testing Methods

To ascertain bond reliability, brands appoint a considerable number of checking out tactics:

These assessments are imperative for caliber guarantee.

Future Trends in Aluminum Wire Bonding Technology

As expertise evolves, so does aluminum twine bonding:

- Innovative Materials: Research into new alloys would possibly escalate performance and decrease charges in addition.

- Automation Advances: Enhanced automation will streamline procedures while bettering precision.

- Miniaturization: As instruments get smaller, suggestions will keep evolving in opposition to finer pitches and tighter tolerances.

This steady evolution guarantees that aluminum stays critical amidst converting technological landscapes.

Conclusion

In summary, aluminum twine bonding performs an necessary role in modern-day electronics production via its various tricks and extensive-ranging programs. Understanding its techniques—from styles of ideas employed to demanding situations confronted—helps engineers and manufacturers alike to harness its complete power accurately.

FAQs

1. What are the principle different types of constituents utilized in wire bonding?

The commonly used constituents used are gold, aluminum, copper, and silver with the aid of their conductive houses and differing fees linked to each and every drapery %%!%%b13e7619-third-416d-8bd7-0401a711c3f5%%!%%.

2. How does thermosonic ball bonding differ from other methods?

Thermosonic ball bonding combines warmness with ultrasonic vitality at some stage in bond formation; this contrasts with in basic terms mechanical or thermal procedures found out in different processes along with wedge or ribbon bonding.

three. What causes influence bond reliability?

Factors include environmental prerequisites (like humidity), cloth houses (akin to oxidation resistance), bond pad layout (measurement/tolerance), and real equipment calibration for the duration of manufacturing runs.

four. Can I automate my existing guide wire-bond tactics?

Yes! Transitioning from manual processes usally requires investing in programmable automated machines which will extensively broaden throughput whereas reducing blunders associated with human handling.

5. What inspections needs to be carried out post-twine bonding?

Common inspections contain visual checks (for obvious defects), pull/shear trying out (to assess bond force), x-ray inspections (for interior themes), along environmental checking out if worthwhile stylish on application specifications.

6. How do I pick among gold vs aluminum for my application?

Consider elements like can charge constraints as opposed to functionality demands; if oxidation resistance isn’t significant yet budget constraints exist—aluminum ought to suffice—while gold suits prime-performance scenarios requiring most advantageous reliability.

This complete discussion on "Aluminum Wire Bonding: Methods and Applications" serves as each a ebook and reference factor for these trying to deepen their realizing of this necessary expertise inside electronics manufacturing right now!