Choosing a Ribbon Bonding Machine: Key Considerations

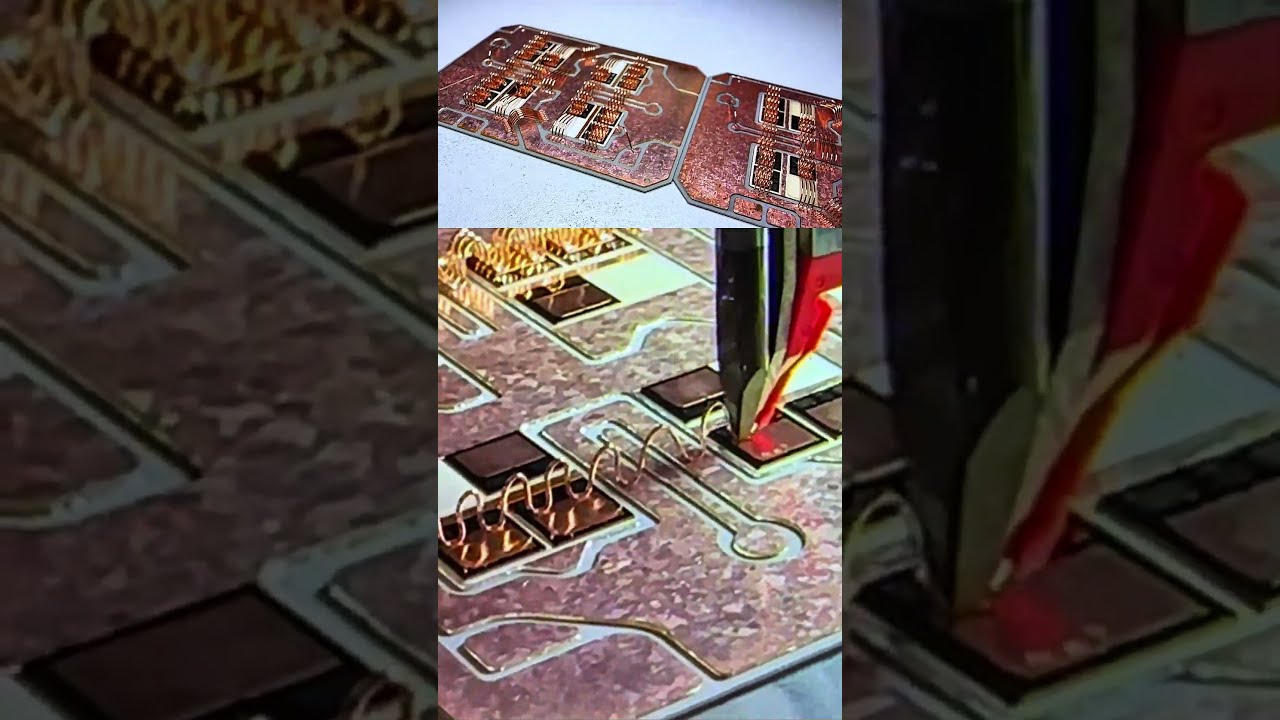

Introduction to Ribbon Bonding

In the sector of semiconductor manufacturing and electronic assembly, the twine bonding procedure plays processes a pivotal position. Among the alternative methods obtainable, ribbon bonding has emerged as a exceptionally strong technique for creating official electric connections in included circuits (ICs) and energy modules. This article delves into Choosing a Ribbon Bonding Machine: Key Considerations, offering insights into what makes a fine ribbon bonding computer, its purposes, and elements influencing your option.

Understanding the Wire Bonding Process

Before we dive into ribbon bonding specially, this is indispensable to be aware of the wider context of wire bonding. The twine bonding activity comprises connecting semiconductor devices or formula utilising pleasant wires crafted from constituents consisting of gold, aluminum, copper, or silver. These connections are foremost for making sure electric alerts can commute between distinctive ingredients of an electronic software.

Types of Wire Bonding Techniques

There are quite a few wire bonding options used in electronics:

-

Ball Bonding: Involves forming a ball on the cease of a twine due to warmth and ultrasonic potential prior to making touch with the bond pad.

-

Wedge Bonding: Utilizes a wedge-formed tool to create bonds by way of applying drive other than heat.

-

Ribbon Bonding: Employs flat ribbons other than round wires, which will be helpful for distinct applications like drive modules.

What is Ribbon Bonding?

Ribbon bonding is a really expert kind of cord bonding the place flat, rectangular ribbons are used as opposed to common around wires. This procedure lets in for enhanced bond region and can bring about improved thermal efficiency and diminished inductance – essential components in prime-frequency packages.

Applications of Ribbon Bonding

Ribbon bonding is peculiarly effective in:

-

Power Modules: Where excessive modern wearing skill is indispensable.

-

LED Manufacturing: For useful thermal management.

-

Automotive Electronics: Where reliability and longevity are paramount.

Choosing a Ribbon Bonding Machine: Key Considerations

When it involves determining a ribbon bonding system, there are a lot of causes you need to take note of to be certain you are making an counseled decision that matches your creation wishes.

1. Types of Ribbon Bonding Machines

There are basically two different types of ribbon bonding machines:

-

Manual Ribbon Bonders: Require an operator's intervention for every single bond however present flexibility in low-amount conditions.

-

Automatic Ribbon Bonders: Designed for prime-amount construction with computerized processes making sure consistency and performance.

2. Size and Configuration

The measurement of the ribbon bonding mechanical device matters. You need to evaluate your workspace and take into consideration whether you require compact items for small spaces or greater setups for enormous operations.

Machine Configuration Options

- Horizontal vs. Vertical Configuration

- Single vs. Multi-head Machines

three. Material Compatibility

Different ribbon bonding machines assist diversified resources—gold, aluminum, or copper ribbons. Ensure that your selected tools can manage the one-of-a-kind components you propose to apply established for your application specifications.

4. Speed and Throughput Capacity

The pace at which bonds could be made immediately influences productivity levels. Evaluate what number bonds per hour the laptop can give as compared for your creation goals.

five. Customization Options

Certain manufacturers provide customizable machines tailor-made to extraordinary demands along with various bond sizes or approaches used (i.e., thermosonic vs. ultrasonic).

6. User Interface and Control Systems

A consumer-pleasant interface complements operational effectivity by means of chopping classes time for body of workers concerned in operating the equipment.

7. Maintenance Requirements

Understanding renovation exercises supports save you sudden downtimes that can prevent creation schedules.

eight. Cost Implications

Budget constraints might also restrict your selections; but, it is considered necessary now not in basic terms to reflect on initial buy expenditures however also lengthy-time period operational fees (including protection).

Frequently Asked Questions (FAQs)

FAQ 1: What is the normal improvement of because of ribbon bonding over natural twine bonding?

Ribbon bonding provides greater floor region contacts that strengthen thermal functionality and reduce inductance—making it most reliable for prime-frequency programs.

FAQ 2: How does one decide which materials is best suited applicable for their wire bonds?

The possibility by and large is dependent on motives like fee-effectiveness, environmental situations (corrosion), mechanical stresses, and electric conductivity standards valuable to the program at hand.

FAQ three: Can ribbon bonders be used for microelectronics?

Yes! Ribbon bonders were quite simply employed in microelectronics in which smaller sizes result in gigantic overall performance upgrades even as maintaining reliability necessities.

FAQ four: Are computerized ribbon bonders extra luxurious than handbook ones?

Yes, automated strategies generally come at top charges with the aid of their evolved expertise features; notwithstanding, they incessantly pay off by means of elevated productivity over time.

FAQ 5: How does one be sure that steady high-quality handle right through ribbon bonding?

Implementing rigorous inspection protocols which includes visual inspections or automated trying out tricks guarantees that any defects arising during creation might be instantly pointed out and rectified in the past they have an effect on closing products adversely.

FAQ 6: What type of working towards is needed for running those machines appropriately?

Operators deserve to take delivery of finished coaching covering the two theoretical components—inclusive of expertise assorted sorts of bonds—and simple talents with regards to laptop operation itself besides troubleshooting tactics if concerns come up all the way through processing degrees!

Conclusion

Selecting the suitable ribbon bonding computer requires cautious attention throughout varied dimensions—from know-how the technical sides in touch in a number varieties of bonds by evaluating capability quotes linked to possession over time! By targeting key considerations corresponding to subject material compatibility along person interface options although maintaining long term renovation routines in thoughts—you’ll role yourself favorably inside of this aggressive landscape! Investing correctly today will yield big returns day after today enabling seamless integration into ever-evolving technological advancements noticeable across industries worldwide along with aerospace capability electronics medical gadgets automotive sectors between others!

In abstract, this manual on "Choosing a Ribbon Bonding Machine: Key Considerations" ambitions now not best at offering insights that pressure suggested decisions yet also emphasizes asserting fantastic requisites all around any given production technique!