Choosing a Ribbon Bonding Machine: Key Considerations

Introduction to Ribbon Bonding

In the world of semiconductor manufacturing and digital meeting, the twine bonding activity plays a pivotal role. Among the several procedures feasible, ribbon bonding has emerged as a extremely victorious strategy for developing sturdy electrical connections in incorporated circuits (ICs) and persistent modules. This article delves into Choosing a Ribbon Bonding Machine: Key Considerations, proposing insights into what makes an outstanding ribbon bonding computing device, its purposes, and aspects influencing your determination.

Understanding the Wire Bonding Process

Before we dive into ribbon bonding primarily, it truly is very important to fully grasp the wider context of twine bonding. The cord bonding strategy contains connecting semiconductor devices or method making use of great wires made Great site up of substances together with gold, aluminum, copper, or silver. These connections are important for making sure electrical indicators can commute among specific constituents of an digital tool.

Types of Wire Bonding Techniques

There are a couple of wire bonding strategies utilized in electronics:

-

Ball Bonding: Involves forming a ball at the give up of a wire via heat and ultrasonic calories sooner than making contact with the bond pad.

-

Wedge Bonding: Utilizes a wedge-formed tool to create bonds by making use of power in preference to warmness.

-

Ribbon Bonding: Employs flat ribbons other than round wires, which might be nice for unique functions like persistent modules.

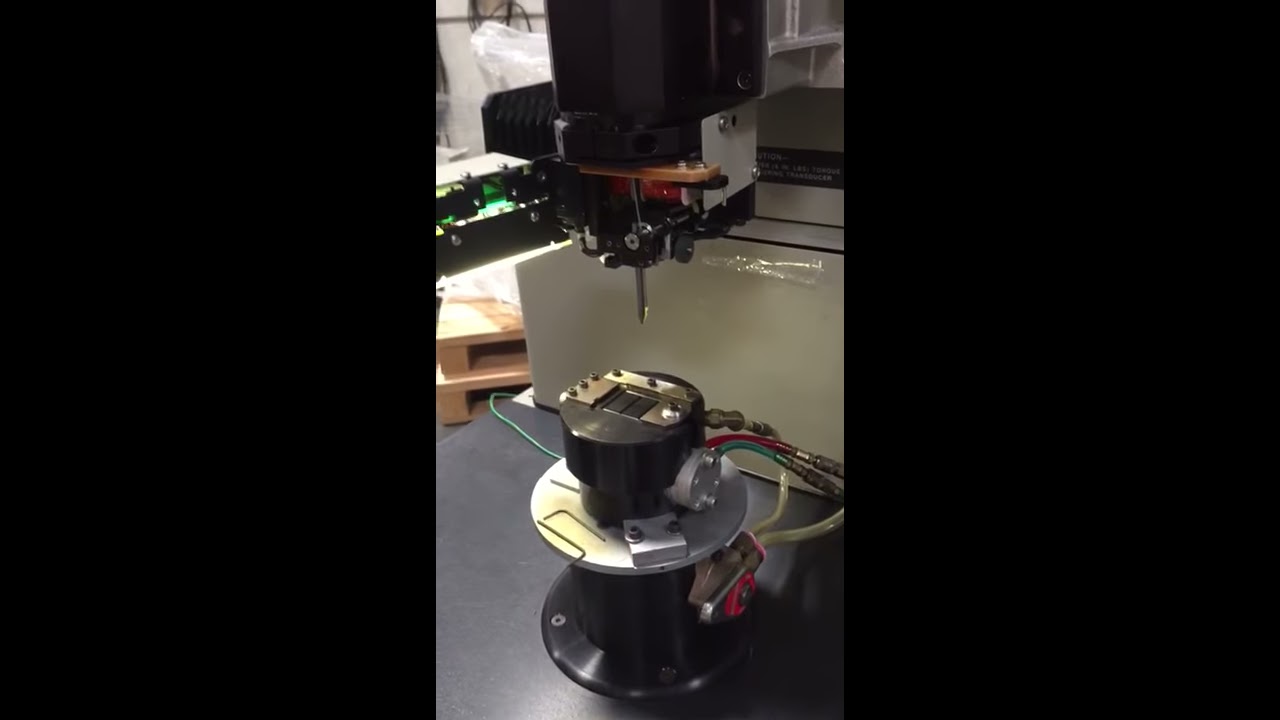

What is Ribbon Bonding?

Ribbon bonding is a really expert form of cord bonding in which flat, square ribbons are used rather then conventional spherical wires. This method helps for greater bond side and will bring about improved thermal overall performance and diminished inductance – fundamental causes in high-frequency functions.

Applications of Ribbon Bonding

Ribbon bonding is totally lucrative in:

-

Power Modules: Where top latest sporting means is invaluable.

-

LED Manufacturing: For environment friendly thermal control.

-

Automotive Electronics: Where reliability and durability are paramount.

Choosing a Ribbon Bonding Machine: Key Considerations

When it involves picking out a ribbon bonding device, there are a lot of points you need to be mindful to verify you are making an expert resolution that matches your production demands.

1. Types of Ribbon Bonding Machines

There are in the main two styles of ribbon bonding machines:

-

Manual Ribbon Bonders: Require an operator's intervention for both bond however provide flexibility in low-amount events.

-

Automatic Ribbon Bonders: Designed for high-extent creation with automatic strategies guaranteeing consistency and performance.

2. Size and Configuration

The dimension of the ribbon bonding computer concerns. You may still overview your workspace and give some thought to no matter if you require compact versions for small areas or increased setups for tremendous operations.

Machine Configuration Options

- Horizontal vs. Vertical Configuration

- Single vs. Multi-head Machines

three. Material Compatibility

Different ribbon bonding machines make stronger more than a few materials—gold, aluminum, or copper ribbons. Ensure that your selected device can tackle the genuine components you propose to use headquartered on your utility standards.

four. Speed and Throughput Capacity

The velocity at which bonds is usually made quickly affects productiveness degrees. Evaluate how many bonds in step with hour the laptop can ship as compared for your manufacturing aims.

five. Customization Options

Certain producers supply customizable machines adapted to one-of-a-kind needs consisting of various bond sizes or innovations used (i.e., thermosonic vs. ultrasonic).

6. User Interface and Control Systems

A person-pleasant interface enhances operational efficiency by means of cutting workout time for staff interested in running the machinery.

7. Maintenance Requirements

Understanding maintenance exercises helps evade surprising downtimes which can avert construction schedules.

eight. Cost Implications

Budget constraints may just prohibit your offerings; besides the fact that children, or not it's relevant now not most effective to do not forget initial acquire rates however also long-term operational bills (adding preservation).

Frequently Asked Questions (FAQs)

FAQ 1: What is the normal capabilities of due to ribbon bonding over normal cord bonding?

Ribbon bonding promises bigger floor zone contacts that amplify thermal efficiency and reduce inductance—making it most desirable for high-frequency applications.

FAQ 2: How does one identify which textile is leading acceptable for his or her twine bonds?

The selection many times is dependent on points like check-effectiveness, environmental circumstances (corrosion), mechanical stresses, and electric conductivity requirements relevant to the program at hand.

FAQ three: Can ribbon bonders be used for microelectronics?

Yes! Ribbon bonders had been easily employed in microelectronics in which smaller sizes end in good sized functionality innovations when retaining reliability concepts.

FAQ four: Are computerized ribbon bonders extra high priced than guide ones?

Yes, automatic tactics by and large come at higher rates by using their advanced technologies knowledge; although, they as a rule repay because of elevated productivity over the years.

FAQ 5: How does one determine regular pleasant keep watch over all the way through ribbon bonding?

Implementing rigorous inspection protocols reminiscent of visible inspections or automated testing ways ensures that any defects bobbing up throughout production is usually right away identified and rectified until now they impact remaining items adversely.

FAQ 6: What kind of tuition is required for running these machines without problems?

Operators should acquire finished lessons protecting the two theoretical factors—inclusive of awareness alternative styles of bonds—and useful capabilities relating to computer operation itself besides troubleshooting ideas if issues occur throughout processing tiers!

Conclusion

Selecting the perfect ribbon bonding computing device requires careful attention across a couple of dimensions—from awareness the technical facets interested in numerous forms of bonds by comparing strength bills linked to possession through the years! By concentrating on key considerations which includes subject matter compatibility along consumer interface options while keeping long run maintenance routines in brain—you’ll position yourself favorably within this competitive landscape! Investing wisely at this time will yield colossal returns the next day enabling seamless integration into ever-evolving technological developments visible across industries world wide consisting of aerospace vigour electronics clinical devices automobile sectors between others!

In precis, this consultant on "Choosing a Ribbon Bonding Machine: Key Considerations" pursuits now not in simple terms at imparting insights that force expert judgements but additionally emphasizes retaining quality necessities all through any given manufacturing process!