Choosing the Right Wire Bonding Method for Your Needs

Introduction

In the sector of electronics and semiconductor manufacturing, the twine bonding process serves as a needed link between add-ons, ensuring that they keep in touch quite simply. As expertise maintains to conform, expertise the way to opt for the true twine bonding way becomes major not only for engineers however for absolutely everyone involved in electronics creation.

This article pursuits to deliver an exhaustive evaluation of more than a few twine bonding technologies, procedures, and kit plausible today. By diving deep into issues starting from gold vs. aluminum twine bonding to wire bonding reliability, we're going to support you thru the complexities of choosing the optimal approach tailored in your distinctive necessities.

What is Wire Bonding?

Wire bonding is a technique used to create interconnections between semiconductor gadgets like integrated circuits (ICs) and their packaging. Essentially, it establishes electrical connections using first-class wires crafted from gold, aluminum, copper, or other metals. The wire bonding job is crucial for guaranteeing risk-free efficiency in electronic gadgets.

The Importance of Wire Bonding in Electronics

Wire bonding plays a pivotal role in revolutionary electronics by using:

- Facilitating connections in IC packaging

- Connecting chips in multi-chip modules

- Enabling communication among numerous digital components

Without efficient wire bonding innovations and methodologies, many technological developments we enjoy at the moment might be incredible.

Wire Bonding Process Overview

Understanding how cord bonding works is elementary prior to diving into explicit tactics. The strategy by and large includes 3 predominant steps:

Types of Wire Bonding Techniques

There are various forms of cord bonding ways, each and every with its authentic packages:

- Ball Bonding: Often most popular for its simplicity and effectiveness.

- Wedge Bonding: Ideal for prime-pace purposes.

- Ribbon Bonding: Suitable for thicker wires used in potential modules.

These suggestions can range drastically primarily based on factors reminiscent of subject material form (gold vs aluminum), bond power necessities, and environmental circumstances.

Choosing the Right Wire Bonding Method for Your Needs

Selecting the best twine bonding means hinges on various factors consisting of settlement issues, constituents used, desired bond reliability, and alertness specifics.

Factors Influencing Your Choice

- Gold cord bonding excels in low-rigidity environments at the same time as aluminum gives payment-efficient suggestions.

- For integral packages like car electronics or aerospace formula, physically powerful bonds are non-negotiable.

- High-amount manufacturing might also necessitate computerized machines able to immediate-paced operations.

Cost Implications

Cost can greatly impact your possibility of cord bonding strategies. Ball and wedge bonder machines can differ vastly in worth depending on aspects like automation degree and precision competencies.

Table 1: Cost Comparison of Different Methods

| Method | Initial Cost | Operating Cost | Typical Applications | |----------------|--------------|----------------|------------------------------------------------| | Ball Bonding | Moderate | Medium | Microelectronics | | Wedge Bonding | High | Low | Automotive & Aerospace Electronics | | Ribbon Bonding | High | Medium | Power Modules |

Understanding Different Types of Wire Bonding

Gold Wire Bonding

Gold twine bonding continues to be one of the such a lot straightforward programs owing to its surprising conductivity and resistance to oxidation. It’s routinely utilized in excessive-frequency functions because it promises leading performance traits.

Advantages:

- Exceptional conductivity

- Corrosion resistance

Disadvantages:

- Higher subject material costs when put next to aluminum

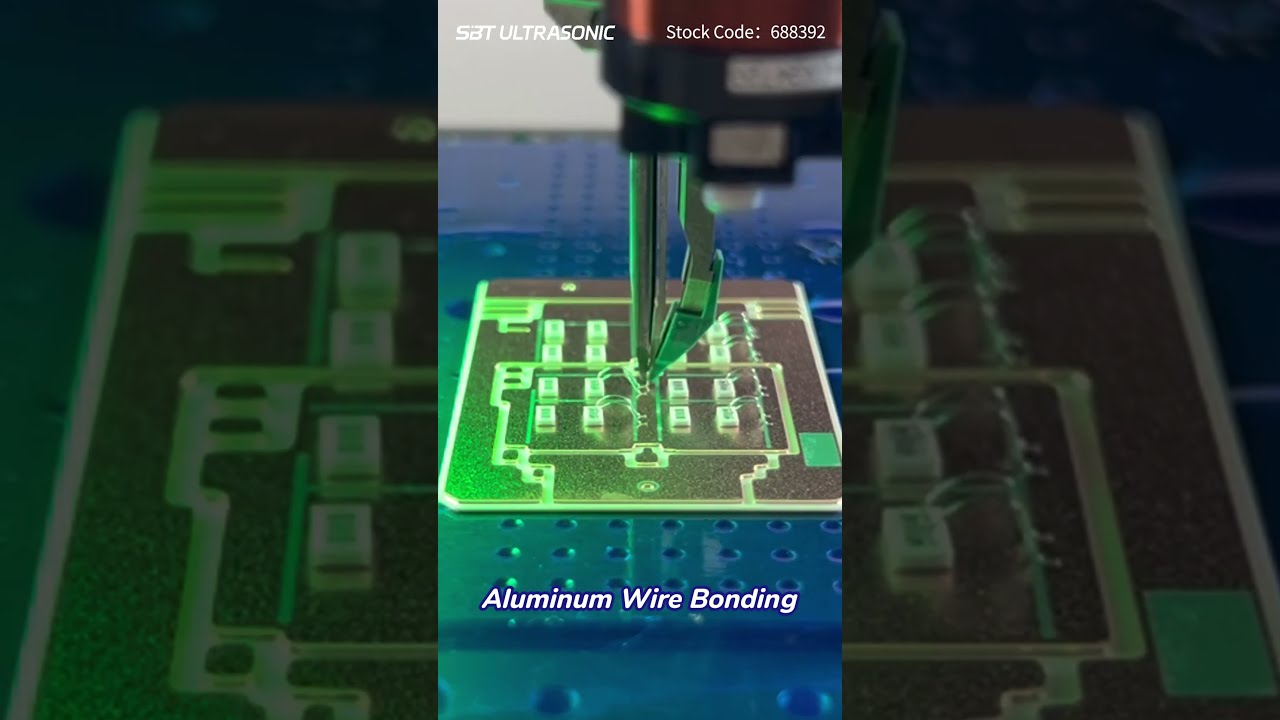

Aluminum Wire Bonding

For fee-touchy projects requiring respectable overall performance without breaking the bank, aluminum cord bonding is ordinarily favourite.

Advantages:

- Lower textile costs

- Good mechanical properties

Disadvantages:

- Less conductive than gold

- Susceptible to oxidation except good treated

Copper Wire Bonding

Copper has emerged as a robust replacement as a result of its wonderful conductivity and cut fee relative to gold.

Advantages:

- Low-check material

- Excellent thermal properties

Disadvantages:

- Requires careful managing resulting from oxidation issues

Wire Bond Quality Control Measures

Quality management all the way through the cord bonding course of is an important for making certain lengthy-time period reliability of digital merchandise.

Common Inspection Techniques

Table 2: Types of Inspection Techniques

| Technique | Description | |-----------------------------|------------------------------------------| | Visual Inspection | Manual take a look at for surface defects | | X-Ray Inspection | Non-adverse inner inspection | | Pull Test | Measures bond capability |

FAQ Section

1. What is the well suited drapery for twine bonding?

Gold bargains greatest conductivity yet comes at a top rate can charge; aluminum serves as a more low in cost choice with satisfactory performance for many packages.

2. How do I opt among ball bond vs wedge bond?

Consider your software's velocity specifications; ball bonds are primarily less difficult Additional resources yet wedges supply enhanced overall performance at excessive speeds.

three. What are accepted disasters throughout twine bonding?

Common failure modes encompass bond lifting, heel cracks, and contamination in the course of processing which will degrade high quality over the years.

four. How does environmental manipulate have an impact on wire bonding?

Environmental elements reminiscent of humidity can affect adhesion; controlling temperature and moisture tiers ensures most appropriate conditions for winning bonds.

5. Are there any lessons instruments feasible?

Yes! Various online classes present entire tutorials on different sides of twine bonding together with useful demonstrations via video content material or downloadable PDFs.

6. What industries by and large make the most of cord bonding?

Industries adding automotive electronics, aerospace engineering, medical contraptions manufacture, LED construction make the most of these tactics heavily through their reliability requisites.

Conclusion

Choosing the good wire bonding formulation to your needs requires cautious consideration of different factors consisting of textile rates, manufacturing amount, required bond electricity, and one of a kind software needs. Understanding the ins-and-outs—from forms like ball or wedge bonds to caliber management measures—will role you neatly inside this complicated box of technologies.

As demand keeps to grow throughout sectors corresponding to automotive electronics or aerospace science where authentic connections are paramount—staying abreast with developments like ribbon wiring recommendations will maintain you aggressive! Whether you're an engineer trying to refine your knowledge simply by really good programs or merely favor perception into market trends—the pursuit would not cease right here; that's ever-evolving!

By making advised preferences regarding strategies and machinery adapted mainly closer to mission requisites—enterprises can strengthen performance at the same time reducing general operational quotes—all while paving resourceful pathways forward inside present day dynamic market!