Exploring Ribbon Bonding Applications in Diverse Industries

Introduction

In the area of electronics and semiconductor manufacturing, cord bonding has emerged as a valuable strategy for starting electrical connections between constituents. Among the plenty of tips of twine bonding, ribbon bonding stands out as a consequence of its individual reward and versatility throughout dissimilar industries. This article delves into the elaborate landscape of ribbon bonding functions, exploring how this leading edge know-how is revolutionizing sectors which include automobile, aerospace, clinical contraptions, and more.

What is Wire Bonding?

Wire bonding is a task used to create electrical connections among semiconductor contraptions and their packaging. It consists of driving skinny wires to attach bond pads on an incorporated circuit (IC) to outside leads or other chips. The well-known intention of wire bonding is to make certain risk-free and helpful verbal exchange inside digital devices.

How Wire Bonding Works

The twine bonding manner pretty much involves various steps:

This technique can utilize a range of sorts of supplies such as gold, aluminum, copper, and silver wire bonding systems.

Types of Wire Bonding Techniques

- Ball Bonding: Utilizes a small ball formed at the end of the twine for connections.

- Wedge Bonding: Employs a wedge-fashioned instrument other than a ball for making connections.

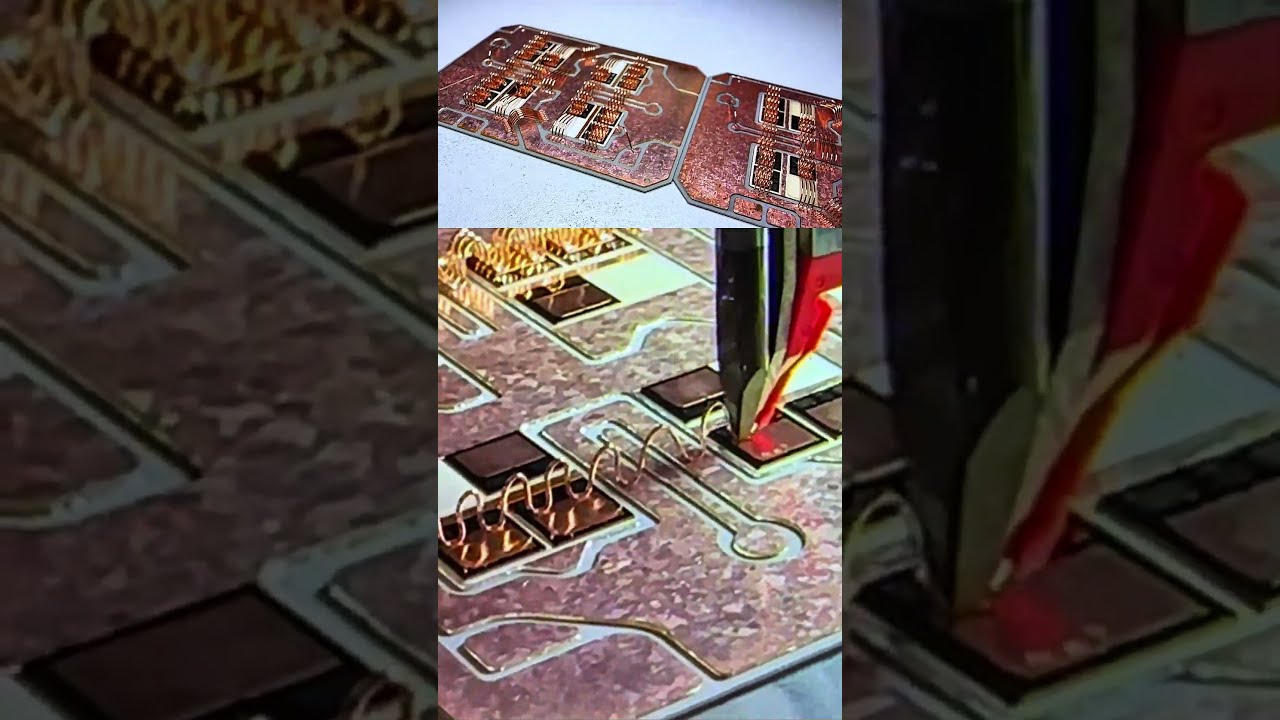

- Ribbon Bonding: Uses flat ribbons in place of spherical wires to make electric connections.

In precis, wisdom those basics units the stage for diving deeper into ribbon bonding certainly.

Visit this siteThe Ribbon Bonding Process

Ribbon bonding is a complicated sort of wire bonding that makes use of flat ribbons rather then around wires. This manner has gained traction on account of its skill to address top recent densities and furnish minimize inductance paths when put next to standard spherical wires.

Advantages of Ribbon Bonding

Ribbon Bonding Machine Overview

A specialized ribbon bonding machine is obligatory for executing this method competently. These machines are designed with services that allow suitable handle over parameters like temperature and power during bonding.

Exploring Ribbon Bonding Applications in Diverse Industries

The versatility of ribbon bonding makes it perfect in quite a few fields including:

1. Automotive Electronics

In latest vans wherein electronic systems are crucial for method like sensors and infotainment strategies, ribbon bonding affords reliability beneath harsh circumstances.

Applications

- Power modules

- Sensor interfaces

2. Aerospace

Aerospace applications require lightweight but powerful strategies; subsequently, ribbon bonding science delivers efficient efficiency at the same time adhering to strict weight regulations.

Applications

- Satellite conversation systems

- Flight keep an eye on systems

three. Medical Devices

Medical instruments necessitate reliability the place human lives are at stake; subsequently ribbon bonded connections verify minimal failure premiums and lengthy-term reliability.

Applications

- Diagnostic equipment

- Implantable devices

4. Telecommunications

With high documents costs being demanded with the aid of networks lately, ribbon bonding’s low inductance properties make it most effective for RF modules utilized in telecommunications kit.

Applications

- Base station transceivers

- Optical communique devices

Understanding Ribbon Wire Bonding Techniques

Gold vs Aluminum Ribbon Bonding

When choosing fabrics for ribbon bonding, many engineers debate between gold and aluminum ribbons:

| Feature | Gold Ribbon | Aluminum Ribbon | |-----------------------------|----------------------|-----------------------| | Cost | High | Low | | Corrosion Resistance | Excellent | Moderate | | Electrical Conductivity | Superior | Good | | Application | High-stop electronics | General-intention |

In abstract, whereas gold ribbons present top-rated conductivity and corrosion resistance, aluminum can be most excellent where expense is a main issue.

Ribbon Bonding vs Wedge Bonding

Both thoughts have their place in manufacturing; besides the fact that children, they cater to completely different needs based on program requisites:

Comparison Table

| Feature | Ribbon Bonding | Wedge Bonding | |-----------------------------|----------------------|-----------------------| | Material | Flat ribbons | Round or flat wires | | Typical Application | High-density circuits | General IC interconnections | | Process Speed | Faster | Moderate |

While each tools can acquire mighty outcome; engineers sometimes pick structured on express layout constraints which include space barriers or thermal residences.

Challenges in Ribbon Bonding

Despite its advantages, there are demanding situations related to ribbon bonding that desire addressing:

To mitigate these challenges, vendors broadly speaking put money into guidance applications concentrating on satisfactory manage measures adapted exceptionally for ribbon bonding procedures.

FAQs About Ribbon Bonding

1. What industries in particular use ribbon bonding?

Ribbon bonding finds purposes commonly in car electronics, aerospace manufacturing, clinical contraptions creation, and telecommunications sectors due to the its authentic benefits over typical tactics.

2. How does ribbon dimension impact functionality?

Larger ribbon sizes pretty much permit greater current capacities but may come with change-offs on the topic of mechanical flexibility or thermal dissipation characteristics; for this reason cautious consideration is critical based on program demands.

three. Can I use any variety of cloth for ribbon bonding?

While aluminum and gold are well-liked decisions on account of their conductivity homes; it's obligatory to evaluate compatibility together with your unique software formerly settling on any drapery type for optimum consequences.

four. What points outcomes bond power all the way through the strategy?

Factors contain subject matter fashion used (gold vs aluminum), ambient operating situations (temperature/humidity), adhesion thoughts hired (ultrasonic vs thermosonic), between others which all play central roles influencing universal bond integrity submit-job of completion.

5. Are there exercise assets achieveable for mastering about cord/ribbon bonding?

Yes! Numerous universities present guides concentrated on facets surrounding current recommendations like the ones fascinated with the two cord & certainly inside of spaces relevant in an instant in opposition to wonderful implementation procedures around employing this know-how effectually!

6. What's subsequent for ribbon know-how improvements?

As demand continues increasing across distinct sectors witnessing improvements on a daily basis—from stepped forward automation capabilities via AI integration fostering smarter resolution-making methods—to more desirable material stories paving method closer to novel programs increasing past traditional utilizations seen today!

Conclusion

In conclusion, exploring ribbon bonding purposes exhibits its pivotal position across numerous industries from car electronics to scientific instruments and past. By leveraging its exciting attributes including high present day capability and decreased inductance pathways—engineers can drive innovation although guaranteeing reliability inside their designs! As we pass forward into an period fueled by immediate technological improvements—ribbon bonds will definitely continue to be at forefront shaping destiny landscapes inside electronic manufacturing nation-states!

This article no longer simply highlights fundamental elements related to “Exploring Ribbon Bonding Applications in Diverse Industries,” however also serves as an informative resource geared toward modifying knowing surrounding tactics imperative toward advancing engineering practices moving ahead!