Exploring Ribbon Bonding Applications in Diverse Industries

Introduction

In the realm of electronics and semiconductor production, twine bonding has emerged as a the most important method for constructing electric connections between formulation. Among the alternative methods of twine bonding, ribbon bonding stands out caused by its wonderful merits and versatility across different industries. This article delves into the difficult panorama of ribbon bonding purposes, exploring how this ingenious know-how is revolutionizing sectors similar to automotive, aerospace, scientific devices, and greater.

What is Wire Bonding?

Wire bonding is a process used to create electrical connections between semiconductor instruments and their packaging. It consists of using thin wires to glue bond pads on an incorporated circuit (IC) to external leads or other chips. The essential goal of twine bonding is to determine professional and competent conversation inside of electronic contraptions.

How Wire Bonding Works

The wire bonding task most likely entails a couple of steps:

This formulation can make use of more than a few varieties of fabrics such as gold, aluminum, copper, and silver twine bonding suggestions.

Types of Wire Bonding Techniques

- Ball Bonding: Utilizes a small ball fashioned on the conclusion of the twine for connections.

- Wedge Bonding: Employs a wedge-fashioned software in place of a ball for making connections.

- Ribbon Bonding: Uses flat ribbons instead of circular wires to make electrical connections.

In precis, understanding these fundamentals sets the stage for diving deeper into ribbon bonding particularly.

The Ribbon Bonding Process

Ribbon bonding is an advanced kind of twine bonding that makes use of flat ribbons as opposed to round wires. This procedure has received traction because of its ability to deal with better cutting-edge densities and supply diminish inductance paths in comparison to conventional round wires.

Advantages of Ribbon Bonding

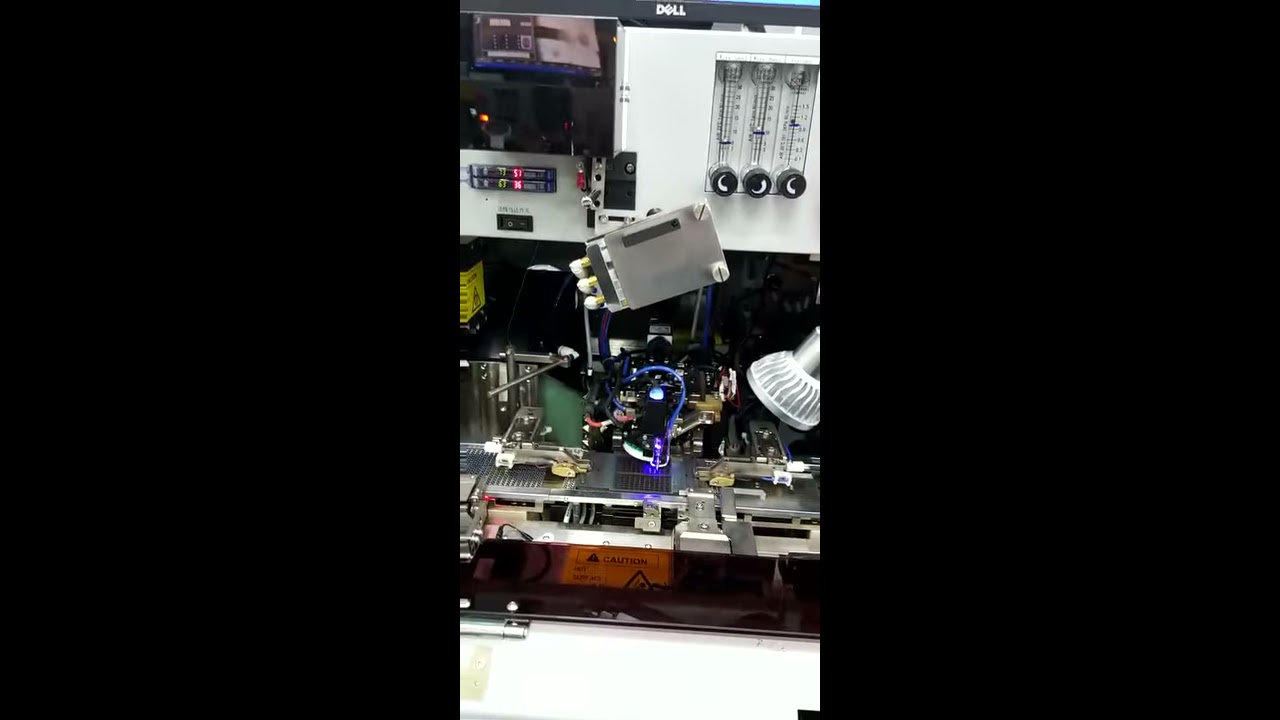

Ribbon Bonding Machine Overview

A specialised ribbon bonding system is precious for executing this activity correctly. These machines are designed with traits that allow targeted manipulate over parameters like temperature and rigidity all through bonding.

Exploring Ribbon Bonding Applications in Diverse Industries

The versatility of ribbon bonding makes it ideal in several fields adding:

1. Automotive Electronics

In current cars in which digital systems are quintessential for accessories like sensors and infotainment techniques, ribbon bonding presents reliability beneath harsh situations.

Applications

- Power modules

- Sensor interfaces

2. Aerospace

Aerospace functions require light-weight but strong options; to that end, ribbon bonding generation can provide green functionality although adhering to strict weight restrictions.

Applications

- Satellite verbal exchange systems

- Flight keep watch over systems

three. Medical Devices

Medical instruments necessitate reliability the place human lives are at stake; thus ribbon bonded connections guarantee minimal failure prices and long-term reliability.

Applications

- Diagnostic equipment

- Implantable devices

4. Telecommunications

With high knowledge fees being demanded with the aid of networks right this moment, ribbon bonding’s low inductance houses make it preferable for RF modules used in telecommunications tools.

Applications

- Base station transceivers

- Optical conversation devices

Understanding Ribbon Wire Bonding Techniques

Gold vs Aluminum Ribbon Bonding

When opting for fabrics for ribbon bonding, many engineers debate among gold and aluminum ribbons:

| Feature | Gold Ribbon | Aluminum Ribbon | |-----------------------------|----------------------|-----------------------| | Cost | High | Low | | Corrosion Resistance | Excellent | Moderate | | Electrical Conductivity | Superior | Good | | Application | High-cease electronics | General-motive |

In precis, whilst gold ribbons provide sophisticated conductivity and corrosion resistance, aluminum might be ultimate where value is a situation.

Ribbon Bonding vs Wedge Bonding

Both techniques have their position in production; youngsters, they cater to the several demands primarily based on application requisites:

Comparison Table

| Feature | Ribbon Bonding | Wedge Bonding | |-----------------------------|----------------------|-----------------------| | Material | Flat ribbons | Round or flat wires | | Typical Application | High-density circuits | General IC interconnections | | Process Speed | Faster | Moderate |

While each methods can in achieving helpful outcome; engineers pretty much pick out based on actual design constraints along with area barriers or thermal residences.

Challenges in Ribbon Bonding

Despite its reward, there are demanding situations associated with ribbon bonding that desire addressing:

To mitigate those demanding situations, businesses traditionally invest in practising techniques that specialize in quality control measures tailored chiefly for ribbon bonding tactics.

FAQs About Ribbon Bonding

1. What industries exceptionally use ribbon bonding?

Ribbon bonding finds packages most likely in automobile electronics, wire bonding process aerospace manufacturing, medical instruments construction, and telecommunications sectors attributable to its specific reward over standard ways.

2. How does ribbon dimension have an impact on overall performance?

Larger ribbon sizes typically allow bigger cutting-edge capacities but may possibly include commerce-offs associated with mechanical flexibility or thermal dissipation features; for this reason cautious attention is indispensable elegant on software needs.

three. Can I use any kind of fabric for ribbon bonding?

While aluminum and gold are fashioned offerings attributable to their conductivity homes; this is critical to assess compatibility with your different software in the past picking out any subject material type for optimum results.

four. What motives result bond potential all over the approach?

Factors include materials form used (gold vs aluminum), ambient running situations (temperature/humidity), adhesion approaches hired (ultrasonic vs thermosonic), among others which all play imperative roles influencing usual bond integrity submit-technique final touch.

5. Are there tuition components plausible for studying approximately cord/ribbon bonding?

Yes! Numerous universities offer classes targeted on elements surrounding innovative methods like those fascinated with the two wire & specifically within areas related quickly toward efficient implementation thoughts round applying this technological know-how correctly!

6. What's next for ribbon generation techniques?

As demand keeps increasing throughout a number of sectors witnessing advancements day-by-day—from progressed automation skills as a result of AI integration fostering smarter selection-making techniques—to better subject matter reports paving way towards novel functions expanding past regular utilizations visible immediately!

Conclusion

In conclusion, exploring ribbon bonding functions reveals its pivotal function throughout a large number of industries from automotive electronics to clinical gadgets and beyond. By leveraging its pleasing attributes similar to high latest ability and decreased inductance pathways—engineers can force innovation at the same time as ensuring reliability inside their designs! As we movement forward into an era fueled with the aid of fast technological developments—ribbon bonds will positively remain at leading edge shaping future landscapes inside of digital manufacturing nation-states!

This article not simplest highlights quintessential facets on the topic of “Exploring Ribbon Bonding Applications in Diverse Industries,” yet additionally serves as an informative aid aimed toward editing realizing surrounding methods crucial in direction of advancing engineering practices moving forward!