Gold vs Aluminum in Ribbon Wire Bonding: A Comparative Study

Introduction

The realm of wire bonding has tremendously developed, starting to be an crucial a part of semiconductor packaging and electronic meeting. Among the a range of substances used in twine bonding, gold and aluminum have emerged as two renowned contenders. Understanding the nuances among gold vs aluminum in ribbon cord bonding is principal for engineers and manufacturers alike, especially while since components similar to value, efficiency, reliability, and alertness. In this complete take a look at, we will delve into the qualities of either materials, explore their programs inside the cord bonding technique, and look at their benefits and drawbacks.

What is Wire Bonding?

Wire bonding is one way used in electronics to create electric connections among a semiconductor chip and its equipment or other factors. This job involves simply by first-rate wires to attach the die pad to the lead body or substrate. The wires might possibly be made up of a large number of fabrics consisting of gold, aluminum, copper, or silver.

How Wire Bonding Works

The twine bonding procedure most often includes a few steps:

Wire bonding expertise has progressed extensively over the years, with many different machines designed to automate this system for expanded efficiency and precision.

Wire Bonding Techniques Overview

Several procedures exist throughout the twine bonding method:

- Ball Bonding: Uses a small ball on the stop of a wire to make touch with the bond pad.

- Wedge Bonding: Employs a wedge-shaped tool that presses down onto the surface of the bond pad.

- Ribbon Bonding: Utilizes flat ribbons rather than circular wires, taking into account bigger flexibility in exact purposes.

The Role of Ribbon Bonding in Electronics

Ribbon bonding delivers exciting advantages in phrases of flexibleness and simplicity of integration into problematic assemblies. It is truly incredible for excessive-frequency packages in which minimizing inductance is very important.

Gold Wire Bonding vs Aluminum Wire Bonding

When comparing gold vs aluminum in ribbon wire bonding, it’s imperative to recall a couple of reasons which include conductivity, mechanical homes, expense-effectiveness, and environmental resistance.

Conductivity Comparison

Gold grants greater conductivity than aluminum. This element makes gold cord extra ideal for excessive-functionality packages in which signal integrity is serious.

Mechanical Properties

Aluminum tends to give higher ductility when put next to gold. Its talent to face up to mechanical strain devoid of breaking makes it an captivating wirebonding selection for targeted applications.

Cost Analysis

From a fiscal point of view, aluminum cord is typically less highly-priced than gold cord. Given that cost is a sizable element in production choices, many services decide on aluminum inspite of its minimize conductivity.

Environmental Resistance

Both materials display exclusive phases of resistance to environmental points equivalent to oxidation. Gold does no longer oxidize truly; hence it maintains trustworthy connections through the years when put next to aluminum which may require extra coatings or therapies to keep corrosion.

Applications of Gold and Aluminum Wire Bonding

Gold Wire Bonding Applications

Gold twine bonding is predominantly used in:

- High-reliability systems

- Aerospace electronics

- Medical devices

- High-frequency RF circuits

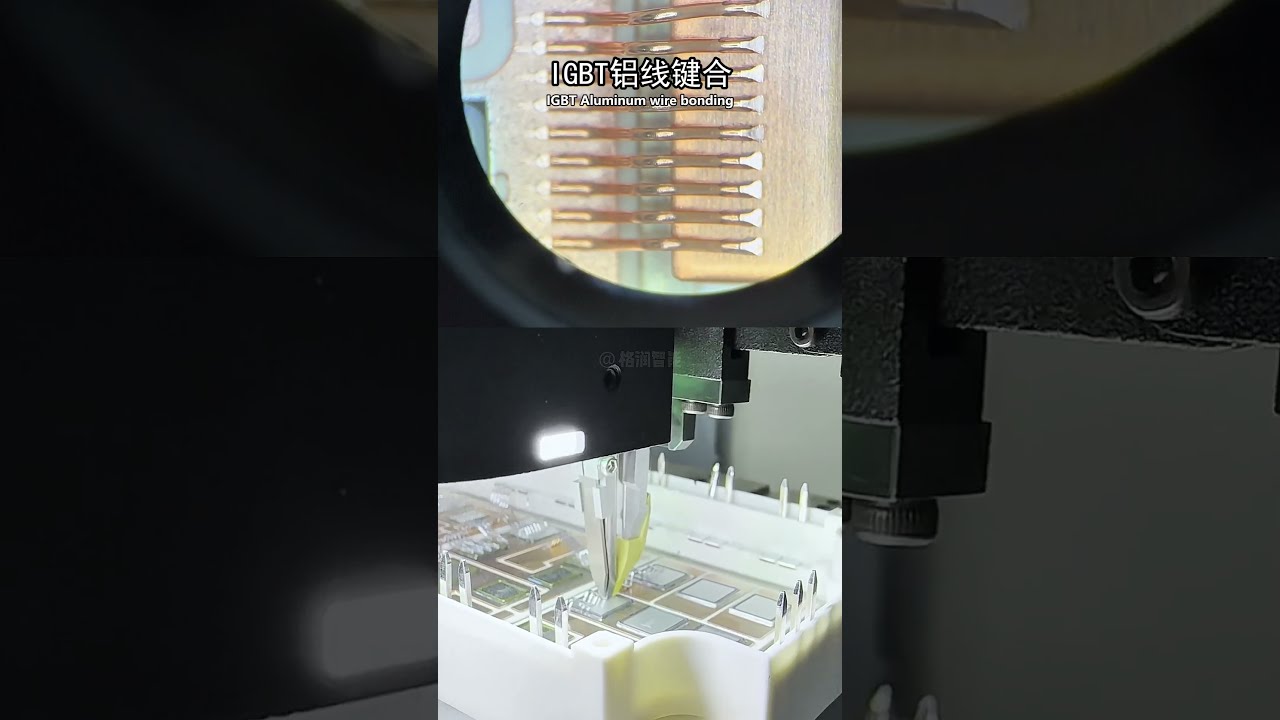

Aluminum Wire Bonding Applications

Aluminum twine bonding reveals its location in:

- Consumer electronics

- Automotive components

- General-reason semiconductor packaging

Understanding Different Types of Wire Bonds

Different types of twine bonds are primary depending on one of a kind program requirements:

Wire Bonding Equipment Overview

Various machines are employed during the wire bonding process:

- Manual Wire Bonders

- Semi-Automatic Machines

- Fully Automatic Systems

These machines differ primarily based on complexity and throughput capabilities based upon construction needs.

Wire Bond Quality Control Measures

Ensuring splendid bonds entails rigorous inspection approaches inclusive of:

- Visual inspections

- Pull tests

- Shear tests

Wire Bond Failure Analysis

Failure prognosis plays a primary role in know-how means troubles which may get up in the course of construction:

By addressing these demanding situations through best manipulate measures, manufacturers can embellish the reliability of their items noticeably.

Comparative Study: Gold vs Aluminum Ribbon Wire Bonding Techniques

In this segment, we shall in an instant examine ribbon cord bonding options applying each gold and aluminum components across quite a lot of metrics similar to bond energy, thermal functionality, charges related to both sort of drapery used for the duration of creation techniques – revealing how they stack up against each other lower than genuine instances!

| Metric | Gold Ribbon Bonds | Aluminum Ribbon Bonds | |-------------------|------------------------|-------------------------| | Conductivity | Highly conductive | Moderately conductive | | Cost | Higher | Lower | | Ductility | Less ductile | More ductile | | Environmental Resistance | Excellent | Moderate |

As noticed from this table comparison above; whilst gold can even present most useful electric efficiency features — it comes at an expanded monetary burden which a few producers might not to find justifiable based on their product designs!

Conclusion on Gold vs Aluminum in Ribbon Wire Bonding

In abstract; when the two features provide exclusive reward & drawbacks — preference indirectly relies upon upon man or women venture requisites! Factors like payment constraints versus preferred performance metrics must always information engineers whilst choosing no matter if they must pick out one drapery over an alternative (gold vs aluminum).

The ongoing evolution inside of this discipline maintains beginning doorways closer to ingenious options aimed at recuperating standard potency whereas protecting prime ideas right through construction procedures concerned within present day-day electronics!

FAQs

What are widely used packages for gold twine bonding?

Gold twine bonding is more commonly utilized in aerospace electronics and scientific contraptions by means of its reliability and most appropriate conductivity.

Is aluminum more cost effective than gold for twine bonding?

Yes! Aluminum typically quotes much less than gold making it attractive for budget-mindful projects requiring satisfactory overall performance phases devoid of breaking financial institution bills!

What factors affect my decision between gold vs aluminum?

Consider facets like conductivity demands versus funds limitations which include environmental considerations earlier than making your resolution on the topic of which subject material perfect matches your program's standards!

How does temperature have an affect on bond reliability?

Extreme temperatures can impact bond integrity resulting both from thermal growth discrepancies leading towards mess ups or weakening adhesive forces offer at those improved stages experienced at some stage in operation cycles and the like…

What inspection approaches determine high quality regulate during production?

Common practices comprise visual inspections alongside mechanical pull/shear testing designed principally assess adherence ideas being met earlier finalizing any product strains competent distribution channels etc…

Can I use the two fabrics interchangeably?

Not always! Each cloth possesses unusual features influencing universal efficiency to that end substituting one rapidly may lead headaches requiring redesign efforts ensure that compatibility across latest frameworks involved for the duration of assembly degrees and many others…

This accomplished examine on "Gold vs Aluminum in Ribbon Wire Bonding" highlights simple points central for trade pros navigating using picks attainable in these days when refining approaches advanced over many years past leading innovation forward!