Real-World Applications of Wedge Bon...

Introduction

In the short-paced world of electronics production, expertise diversified bonding ways is fundamental for generating secure and powerfuble gadgets. One such technique that has gained titanic traction in contemporary years is wedge bonding. This article will delve into the genuine-international applications of wedge bonding, exploring its reward, ways, and a considerable number of sectors it serves. From semiconductors to medical gadgets and all the pieces in between, we’ll reflect on how this technology is transforming industries whilst keeping top concepts in exceptional and reliability.

What is Wedge Bonding?

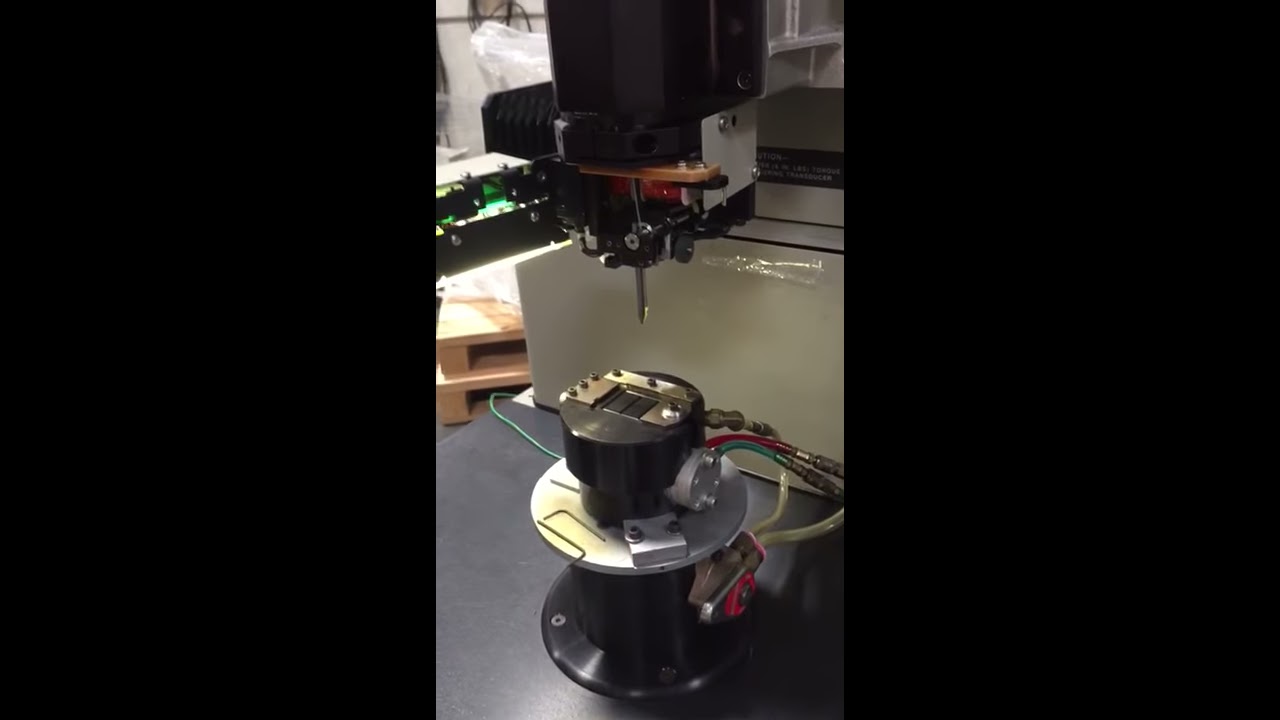

Wedge bonding is a wire bonding task involving a wedge-formed device that creates connections between semiconductor instruments and substrates. It’s broadly used in a considerable number of fields thanks to its talent to grant sturdy electric interconnections with minimum mechanical stress. Understanding the nuances of this approach can provide insights into why it has was a most well-liked selection between brands.

How Wedge Bonding Works

The method starts with positioning the wire over the bonding pad at the semiconductor device. The wedge software applies ultrasonic potential or heat (based on whether or not it's ultrasonic or thermosonic wedge bonding) to facilitate steel go with the flow, creating a good bond. This system enables for fabulous regulate over bond parameters, contributing to high reliability.

Wedge Bonding vs. Other Bonding Techniques

When evaluating wedge bonding with other programs like ball bonding or turn-chip soldering, several elements come into play:

Types of Wedge Bonding Methods

There are a range of types of wedge bonding approaches adapted for special programs:

1. Ultrasonic Wedge Bonding

This system makes use of ultrasonic vigor to create bonds at decrease temperatures, making it precise for touchy elements.

2. Thermosonic Wedge Bonding

Combining warmness and ultrasonic vitality, thermosonic wedge bonding enhances subject matter circulation, ensuing in more suitable bonds.

three. Deep Access Wedge Bonding

Ideal for purposes requiring deep entry features wherein simple instruments may well fight.

4. Insulated Wedge Bonding

Incorporates insulation round the twine for superior safeguard in sensitive environments.

Real-World Applications of Wedge Bonding

Now that we have an understanding of what wedge bonding is and its different sorts, let’s discover its actual-world packages across plenty of industries:

1. Semiconductor Manufacturing

Wedge bonding plays a needed function in semiconductor devices' packaging. Its skill to address fantastic pitch leads makes it most well known for smooth microprocessors and reminiscence chips.

Benefits

- High-density packaging

- Reduced thermal resistance

- Enhanced electrical performance

2. Medical Devices

In the medical discipline, the place reliability is usually a topic of life and loss of life, wedge bonding guarantees defend connections in implantable gadgets resembling pacemakers and sensors.

Benefits

- Biocompatibility

- Resistance to environmental components (moisture, temperature)

- High reliability

3. Automotive Electronics

As vehicles changed into increasingly more reliant on electronic techniques for security and efficiency, wedge bonding provides sturdy suggestions for automotive modules including ECUs (Electronic Control Units) and sensors.

Benefits

- Enhanced vibration resistance

- Low-settlement production processes

- Improved long-time period reliability

4. Aerospace Applications

In aerospace expertise, wherein weight discounts are a must-have with no compromising energy or reliability, wedge bonding excels by way of cutting back the dimensions and weight of components even as preserving efficiency integrity.

Benefits

- Lightweight interconnections

- Resistance to severe conditions

- Compliance with stringent protection regulations

five. LED Manufacturing

With LEDs becoming ubiquitous in lighting answers, because of wedge bonding improves connectivity within LED programs with the aid of offering official electric contacts that resist thermal biking rigidity.

Benefits

- Improved easy output efficiency

- Longer lifespan of LED products

- Enhanced thermal administration

Wire Bonding Process Overview

To absolutely savour the significance of wedge bonding within its truly-international purposes, we have got to notice the general twine bonding course of:

Challenges in Wire Bonding Reliability

Despite its a number of advantages, several challenges exist pertaining to cord bonding reliability:

Bond Failures: Common failures encompass heel cracks and bond lifting attributable to mistaken settings or illness.

Oxidation Issues: Oxidation can weaken bonds if genuine precautions aren’t taken at some stage in guidance tiers.

Environmental Factors: Moisture exposure can cause corrosion through the years; therefore protecting coatings are ceaselessly endorsed.

Material Selection: Choosing between gold vs aluminum vs copper twine relies upon on conductivity wants versus rate concerns.

FAQ Section

1. What substances are routinely utilized in wedge bonding?

Wedge bonding primarily makes use of gold and aluminum wires by reason of their ideally suited conductivity and ductility; copper has also emerged as an economical opportunity but comes with oxidation negative aspects that want addressing.

2. How does one confirm fine handle all through cord bonding?

Quality keep watch over entails multiple steps including visual inspections publish-bond advent as well Helpful hints as pull tests that measure bond energy in opposition t ordinary thresholds defined via trade requirements like JEDEC.

3. Can you provide an explanation for the differences between ball bonding and wedge bonding?

Ball bonding kinds a round connection due to heated balls at the quit of wires when wedge bonds use flat surfaces pressed together; both has exotic merits based on application specifications like pitch dimension or environmental prerequisites confronted right through operation.

4. Is there any instructions obtainable for learning twine bonding ways?

Yes! Numerous organisations be offering the two on line guides (probably available as PDFs) in addition to realistic workshops designed peculiarly focusing on engineers seeking deeper experience approximately triumphant practices inside of diversified contexts like semiconductor packaging or automobile electronics integration approaches!

5.What are some known defects encountered for the period of wire bond processing?

Common defects contain incomplete bonds due lack properly drive calibration applied during setup most efficient prospective disasters associated vulnerable connections identified simply by targeted visual inspection protocols prevalent in the time of production lifecycle stages!

6.Are there any improvements presently being researched concerning making improvements to latest methods & technologies utilized as we speak?

Absolutely! Researchers retain exploring progressed ingredients which includes automatic strategies incorporating AI-driven controls aimed optimizing performance metrics along slicing charges average related basic tactics employed historically across a variety of sectors suggested in advance!

Conclusion

Wedge bonding represents a pivotal expertise across many sectors—semiconductors being just one illustration—through delivering authentic connections serious for instrument capability at the same time navigating in direction of ever-increasing calls for referring to density compactness sturdiness predicted from smooth electronic designs! As brands retain adapting their tactics alongside evolving client expectations surrounding high-quality coverage standards rising developments propose even brighter futures wait for these inclined embrace recommendations shaping landscape ahead!