Ribbon vs Wedge Bonding: Making the Right Choice

Introduction

In the area of semiconductor production, twine bonding is a very important job that connects the chip to its bundle, making certain the performance of digital units. Within this complex world, two favourite thoughts have emerged: ribbon bonding and wedge bonding. Each strategy has its possess set of blessings and drawbacks, making the selection between them pivotal for brands. This article will discover those techniques in aspect, highlighting their purposes, blessings, obstacles, and lots more and plenty greater. Whether you're a pro engineer or a newcomer to wire bonding expertise, information the nuances of ribbon vs wedge bonding will empower you to make advised decisions in your projects.

What Is Wire Bonding?

Wire bonding is a manner that establishes electric connections between semiconductor gadgets and their programs through effective wires (basically manufactured from gold, aluminum, copper, or silver). This way has changed into important in today's electronics resulting from its reliability and efficiency in connecting chips to substrates.

The Evolution of Wire Bonding Technology

Wire bonding technological know-how has advanced considerably through the years. Initially ruled by handbook techniques, improvements have ended in automatic tactics capable of performing excessive-precision bonds at notable speeds. With technologies like thermosonic and ultrasonic bonding emerging as trade requirements, manufacturers now have distinct preferences tailor-made to targeted applications.

Key Applications of Wire Bonding

Wire bonding reveals purposes across quite a few sectors:

- Semiconductors: Essential for integrated circuits.

- Automotive Electronics: Used in sensors and handle instruments.

- Medical Devices: Critical for good functionality.

- LED Manufacturing: Ensures fantastic vigour distribution.

Types of Wire Bonding Techniques

When diving deeper into twine bonding methods, it be the most important to appreciate that varying techniques exist beyond just ribbon and wedge bonding.

1. Ball Bonding

Ball bonding makes use of a ball-formed conclusion fashioned at the tip of a gold wire. This technique is time-honored as it affords effective connections with minimal risk of destroy to delicate additives.

2. Wedge Bonding

Wedge bonding employs flat wires in place of spherical ones and uses a wedge software to make connections. This process will probably be beneficial for positive configurations the place area is restrained.

three. Ribbon Bonding

Ribbon bonding utilizes flat ribbons rather than round wires. It’s extremely incredible in high-density purposes wherein bond strength needs to be maximized at the same time sustaining a low profile.

4. Flip Chip Bonding

Though no longer strictly beneath cord bonding tricks, flip chip expertise enables direct electrical connection with out wires by way of solder bumps on chip pads.

5. Hybrid Wire Bonding

This combines totally different recommendations adapted in particular for multi-die applications making certain greatest potency in tricky assemblies.

Understanding Ribbon Bonding Process

Ribbon bondings have faith in flat ribbons constructed from conductive parts comparable to gold or aluminum. The strategy comprises a few crucial steps:

Advantages of Ribbon Bonding

- Higher Current Capacity: Due to larger floor aspect contacts.

- Lower Inductance: Beneficial for high-frequency functions.

- Compact Design: Ideal for dense layouts requiring minimum house.

Limitations of Ribbon Bonding

- Requires really expert device which could increase preliminary expenditures.

- May no longer be applicable for all styles of chips via mechanical stress at some stage in program.

Exploring Wedge Bonding Process

Wedge bonding comes to simply by a wedge-formed software that applies power in the time of bond formation:

Benefits of Wedge Bonding

- Effective in developing effective bonds regardless of irregular surfaces.

- Can make the most of exclusive sorts of fabrics consisting of aluminum and copper wires.

Challenges Associated with Wedge Bonding

- Limited flexibility in contrast to different methods like ball or ribbon bonding.

- Potentially increased prices through device put on if no longer controlled properly.

Ribbon vs Wedge Bonding in IC Packaging

When taking into account IC packaging particularly, both techniques offer designated advantages adapted in the direction of one of a kind necessities:

Ribbon Bonding in IC Packaging

Ideal for packages desiring excessive cutting-edge potential:

- Commonly used in vitality modules where diminish resistance connections are critical.

| Feature | Ribbon Bonding | | ------- | --------------- | | Current Capacity | High | | Inductance | Low | | Application Area | Power Modules |

Wedge Bonding in IC Packaging

Preferred while operating with distinctive drapery sorts:

- Suitable for packaging in which area constraints necessitate compact designs devoid of sacrificing integrity.

| Feature | Wedge Bonding | | ------- | --------------- | | Material Flexibility | High | | Surface Adaptability | Excellent | | Application Area | Multi-Surface Connections |

Wire Bond Equipment Overview

To execute those procedures effectually calls for specialized equipment:

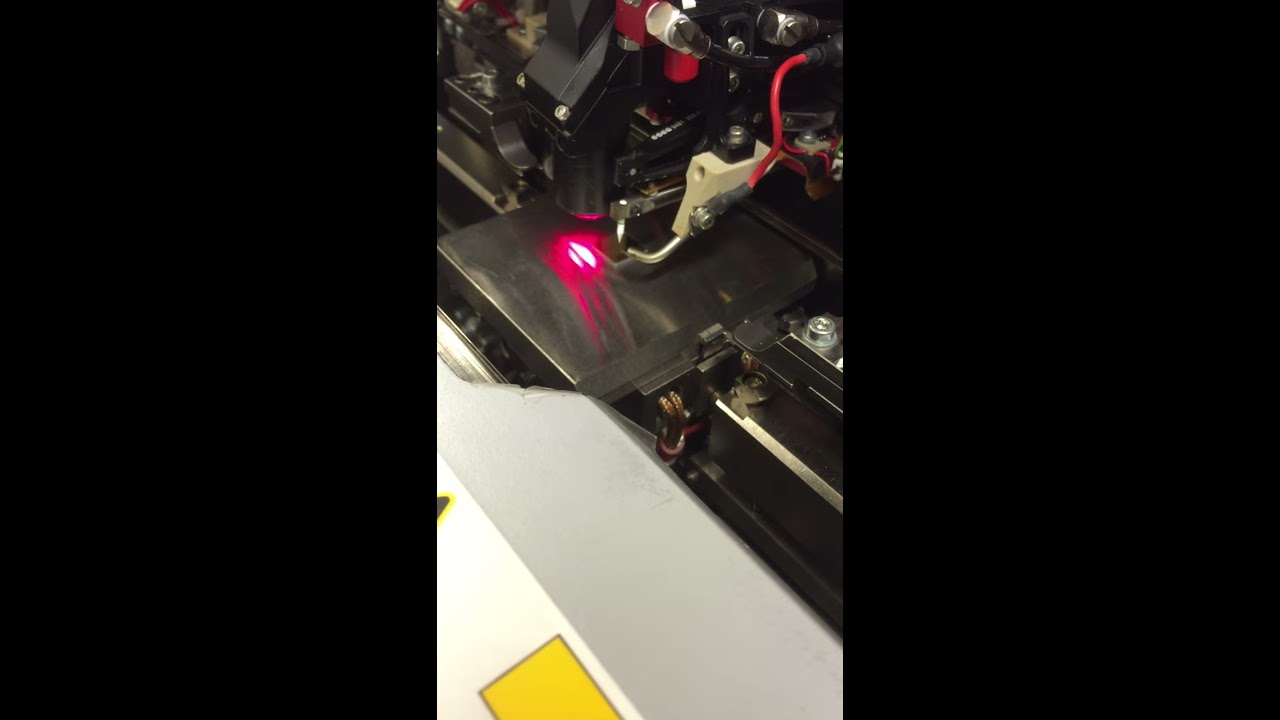

Ribbon Bonding Machines

Designed particularly for coping with ribbons; they arrive in a position with unique heating controls and adjustable parameters perfect for special cloth types.

Key Features

- Adjustable settings for alternative ribbon sizes

- Automated feed mechanisms

- Real-time monitoring systems

Wedge Bonding Tools

These machines comprise complex points enabling operators to positive-song angles and forces exerted throughout the time of bond advent:

Important Aspects

- Compatibility with multiple wire materials

- Enhanced suggestions loops enabling instantaneous modifications stylish on bond quality

Wire Bond Quality Control Measures

Quality handle continues to be paramount for the duration of the overall wire-bond manner—either ribbon and wedge tips require stringent checking out protocols:

Each method offers advantageous insights into prospective weaknesses within bonded interfaces making sure lengthy-term reliability across merchandise manufactured simply by both way.

Cost Considerations in Wire Bond Processes

Evaluating costs associated with every one procedure requires attention past simply machine funding; explanations comprise subject matter expenses (gold vs aluminum), hard work costs related to setup occasions, preservation charges over time including doubtless production yields similar losses due terrible yield premiums linked faulty bonds produced by using much less surest possibilities!

| Aspect | Ribbon Additional info | Wedge | | -------------------- | ---------------------------- | ---------------------------- | | Initial Investment | Higher due specialised equipment | Moderate depending on configuration| | Material Costs | Gold & Aluminum primarily | Aluminum & Copper preferences available| | Maintenance Needs | Regular exams required | Frequent calibration periods mandatory|

Wire Bond Failure Analysis Techniques

Understanding how failures ensue is central in the direction of bettering reliability measures taken inside of respective manufacturing traces; here’s an summary breakdown focusing exceptionally upon elementary themes faced throughout both methodologies employed right now!

Common Failure Modes:

1.Rubbing/Fracture – Caused by way of high drive exerted all the way through bond program top-rated fracture issues appearing publish-cooling cycles 2.Oxidation – Impacts standard bond capability negatively if exposed longer durations outdoors controlled environments! 3.Incomplete Bonds – Result from insufficient heating prerequisites causing inadequate melting optimal vulnerable joins forming among contacts themselves!

Taking proactive steps addressing root motives enormously get well ordinary good fortune charges noticeable all around comprehensive lifecycle product being synthetic as a consequence lowering typical rates incurred!

Conclusion

Ultimately picking out among ribbon vs wedge bonding depends heavily upon specified undertaking necessities which include however now not confined too modern-day means needs house obstacles preferred flexibility within creation capabilities! Both methodologies preserve merit having said that knowing when observe each one respectively ensures larger yields advanced reliability across all digital units synthetic nowadays!

By knowing equally techniques utterly engineers can tailor ideas maximizing effectiveness whilst minimizing doable pitfalls encountered alongside way! The prime intention have to regularly aim closer to generating fine quality merchandise devoid of compromising cost performance ensuring aggressive advantage maintained over competitors operating equally fields alike!

FAQ Section

1️⃣ What is the fundamental change among ribbon and wedge bonding?

The essential big difference lies in their material forms used; ribbons are flat whilst wedges use extra usual spherical wires offering special advantages with regards to density as opposed to energy ratios performed using respective procedures employed!

2️⃣ Are there targeted packages highest appropriate toward both technique?

Yes certainly! Generally talking strength modules favor due to ribbons whereas numerous surfaces generally tend favor wedges offering greater adaptability across various shapes/varieties encountered most of the time inside semiconductor designs!

3️⃣ What causes effect money considerations associated with every one formulation?

Material class utilized performs huge function alongside machine investments vital alongside renovation requisites usual at some point of lifecycle construction runs in particular concerning failure prognosis conducted periodically assessing achievement charges achieved hence!

four️⃣ How does one operate beneficial caliber manage measures within those procedures? Implement visible inspections complemented by way of pull/shear testing protocols making use of x-ray imaging revealing talents flaws current amongst bonds fashioned ensuring consistency upheld at some stage in each and every unit produced in the end bettering overall reliability perceived by means of quit-clients alike!

5️⃣ Can I change from one technique to some other certainly? Switches may perhaps involve additional coaching implementing new equipment setup variations based present workflows already installed requiring diversifications made thus ascertain seamless transitions arise!

6️⃣ What’s the long run outlook referring to improvements happening inside of wire-bond technology? Future potentialities stay promising given ongoing thoughts emerging incessantly within semiconductor industries selling an increasing number of efficient suggestions catering a growing number of advanced needs developing along technological variations witnessed global as we speak!