The Importance of Wire Bonding in Modern Electronics

Introduction

In the at once evolving international of electronics, the call for for effectual, sturdy, and compact designs has not ever been more advantageous. At the middle of many digital contraptions lies a imperative procedure is named wire bonding. This strategy helps electric connections among semiconductor units and their substrates, enjoying a imperative role in making certain function and efficiency. In this article, we shall delve into the value of twine bonding in state-of-the-art electronics, exploring a great number of thoughts, purposes, and applied sciences linked to it.

What is Wire Bonding?

Wire bonding refers to a method used to make electric interconnections among semiconductor chips and outside circuitry, more commonly applying very first-rate wires. The strategy entails attaching those wires to bonding pads on the semiconductor chip and substrate as a result of warmth or ultrasonic vitality. It is a primary element of IC packaging, making sure that contraptions can keep up a correspondence effectually.

The Wire Bonding Process

The twine bonding process carries quite a few key steps:

Key Components of Wire Bonding Technology

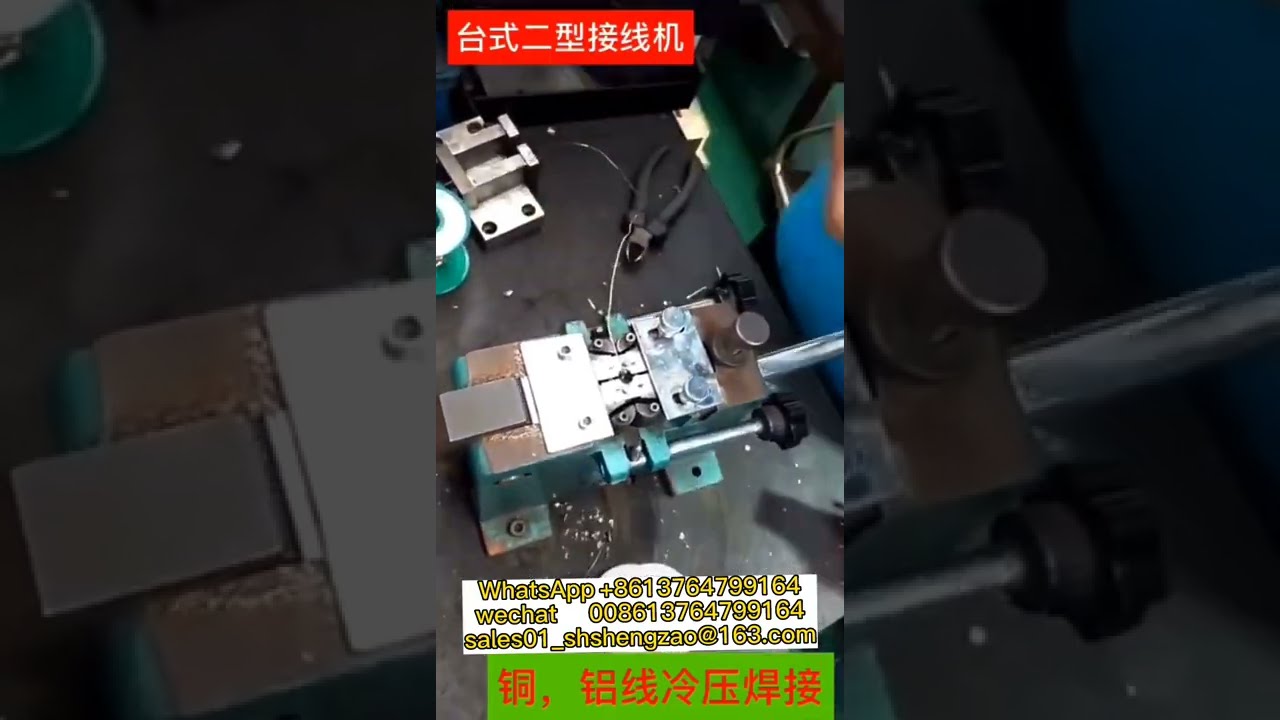

- Wire Bonding Machines: These really good machines execute the bonding course of with precision.

- Bonding Wires: Typically made from gold, aluminum, copper, or silver; each materials deals unusual blessings based mostly on program requirements.

- Bond Pads: The places on chips wherein wires are connected.

Types of Wire Bonding Techniques

Different programs cater to diverse purposes inside electronics:

Ball Bonding

This is some of the so much common systems wherein a small ball is formed at one end of the twine. The ball is then pressed onto the pad the use of warmth and power.

Wedge Bonding

This procedure uses a wedge-formed tool to bond flat wires onto pads devoid of forming balls. It's regularly popular for its reliability in excessive-frequency programs.

Ribbon Bonding

This entails employing flat ribbons rather then spherical wires, taking into account stronger existing handling and lowered inductance.

How Wire Bonding Works

Wire bonding combines standards from mechanical engineering, constituents science, and electrical engineering to create amazing connections. Understanding how cord bonding works aids in appreciating its significance in digital design.

Gold vs Aluminum Wire Bonding

Gold cord bonding remains usual because of the its well suited conductivity and corrosion resistance. However, aluminum is increasingly more applied as a result of diminish rates and enough functionality in less difficult environments.

| Attribute | Gold Wire Bonding | Aluminum Wire Bonding | |--------------------|-----------------------|--------------------------| | Conductivity | High | Moderate | | Cost | Expensive | Affordable | | Corrosion Resistance| Excellent | Moderate |

Wire Bonding Applications

Wire bonding unearths sizeable packages across a lot of sectors:

Semiconductors

In semiconductor manufacturing, wire bonding connects die chips with substrates for built-in circuits (ICs).

Automotive Electronics

With expanding electronic formula in autos, good twine bonds be sure reliable operations throughout platforms consisting of braking or navigation.

Medical Devices

Medical units require stringent reliability necessities; for this reason, effective twine bonding guarantees tough connections at the same time meeting regulatory necessities.

Wire Bonding Reliability Analysis

Reliability is paramount while discussing twine bonds because failures can result in good sized outcomes.

Common Failure Modes in Wire Bonding

- Bond Lifting: Occurs whilst insufficient power or temperature results in weak adhesion.

- Heel Cracks: Stress fractures that come about at the base of bonded wires by using thermal cycling.

Table 2: Common Failure Modes

| Failure Mode | Description | Mitigation Strategies | |--------------------|----------------------------------|-------------------------------------| | Bond Lifting | Weak adhesion | Optimize pressure/temperature settings | | Heel Cracks | Stress fractures | Design with thermal concerns |

Wire Bond Quality Control Techniques

Quality control at some stage in cord bonding approaches ensures that defects are minimized:

Inspection Methods

- Visual Inspection: Basic tests for obvious defects.

- Automated Testing: Utilizing machines supplied with imaging expertise for thorough inspections.

Non-harmful Testing

Non-detrimental testing approaches permit engineers to evaluate bond excellent with out hazardous accessories.

FAQs approximately Wire Bonding

- Common material contain gold, aluminum, copper, and silver—each proposing wonderful houses appropriate for diverse functions.

- Gold famous stronger conductivity and corrosion resistance compared to aluminum yet is more expensive.

- Industries which includes semiconductor production, automobile electronics, clinical gadgets, aerospace technologies, and renewable vitality all gain from cord bonding.

- Numerous resources consisting of publications introduced by way of universities or online systems provide tutorials on stepped forward ways utilized in twine bonding.

- Common subject matters contain bond lifting by reason of insufficient adhesive homes or heel cracks as a result of thermal rigidity at some point of operation cycles.

- Yes! Research maintains into new material and approaches geared toward improving efficiency at the same time decreasing manufacturing expenses.

Conclusion

The value of wire bonding in current electronics should not be overstated; it serves as a bridge aluminum wire bonding connecting a lot of electronic resources inside contraptions ranging from smartphones to scientific accessories. Its versatility lets in it no longer purely to meet however exceed trade principles across diverse sectors whilst adapting alongside technological improvements towards upper potency versions like low-check strategies or automatic procedures.

By awareness both foundational thoughts like styles of strategies conceivable together with life like effects derived simply by rigorous testing methodologies — stakeholders could make expert judgements that subsequently propel their suggestions forward into a success industry positions.

Overall ensuring thorough information on the topic of how those strategies have an impact on product reliability will keep defining long term tendencies shaping our interconnected international at the present time!

In this entire exploration of "The Importance of Wire Bonding in Modern Electronics," we've got protected the whole thing from fundamental definitions and programs by means of complicated analyses on reliability measures taken throughout countless industries benefiting from this necessary era!