Types of Wire Bonding: An In-Depth Exploration

Introduction

In the arena of electronics, the wire bonding technique is a central manner used to determine electric connections between semiconductor contraptions. As we delve into the styles of twine bonding, we are going to discover quite a lot of programs, methods, purposes, and their significance in trendy electronics. Understanding those approaches now not simplest supports engineers go with the precise formula for their specific wants yet also complements reliability and functionality in electronic merchandise. This article serves as a entire information to the different types of wire bonding and their implications on generation.

What is Wire Bonding?

Wire bonding refers to a technique of connecting wires from one aspect on an integrated circuit (IC) or semiconductor gadget to yet one more. This task is pivotal in making sure that digital elements position accurately by means of facilitating verbal exchange and electric alerts. Typically, it contains attaching skinny wires constituted of material like gold, aluminum, copper, or silver onto bonding pads on chips or substrates by way of specialised machines.

The Importance of Wire Bonding in Electronics

The cord bonding course of is most important for a few purposes:

- Electrical Connectivity: It delivers high-quality pathways for contemporary circulate among constituents.

- Mechanical Stability: Properly performed wire bonds assist physical balance for the period of operation.

- Cost Efficiency: Compared to alternative processes like flip-chip bonding or soldering, cord bonding can also be greater in your price range and flexible.

Types of Wire Bonding: An Overview

There are countless kinds of twine bonding methods employed throughout many different programs:

Each methodology has exclusive features acceptable for exceptional situations stylish on components like fabric properties, expense concerns, and required bond force.

Ball Bonding Process

Ball bonding is one of the crucial most straightforward innovations used in microelectronics. It quite often comes to due to a gold or aluminum twine it's heated at its tip to sort a small ball prior to being bonded onto the chip pad.

Advantages of Ball Bonding

- High reliability

- Suitable for high quality pitch applications

- Versatile with many materials

Disadvantages of Ball Bonding

- Limited to softer materials

- Higher expenses when utilizing necessary metals like gold

Wedge Bonding Process

Wedge bonding employs a wedge-shaped software to create bonds with out forming a ball at the wire's stop. It’s in general applied with aluminum or copper wires by reason of its effectiveness with these constituents.

Advantages of Wedge Bonding

- Stronger bonds than ball bonds

- Flexibility with varied materials

- Ideal for better bond areas

Disadvantages of Wedge Bonding

- More advanced tooling

- Potentially slower than ball bonding

Ribbon Bonding Process

Ribbon bonding uses flat ribbon wires rather then round wires. This methodology lets in for broader contact places and can expand electrical functionality in yes top-chronic functions.

Advantages of Ribbon Bonding

- Improved thermal management

- Reduced inductance in top-frequency applications

- Greater floor location for greater adhesion

Disadvantages of Ribbon Bonding

- Requires specialized equipment

- Limited availability in contrast to conventional spherical wires

Hybrid Bonding Process

Hybrid bonding combines other different types of bond technologies (e.g., ball and wedge) within the same assembly job. This versatility makes it relevant for complex electronic assemblies.

Advantages of Hybrid Bonding

- Increased design flexibility

- Enhanced common reliability across diverse connections

Disadvantages of Hybrid Bonding

- More complex setup requiring educated operators

- Potentially bigger prices by means of complexity

Materials Used in Wire Bonding

The resolution of subject material performs a primary role in making a choice on bond high quality and functionality:

Gold Wire Bonding

Gold remains one of the vital so much au ball wire bonding widely used ingredients resulting from its striking conductivity and resistance to corrosion.

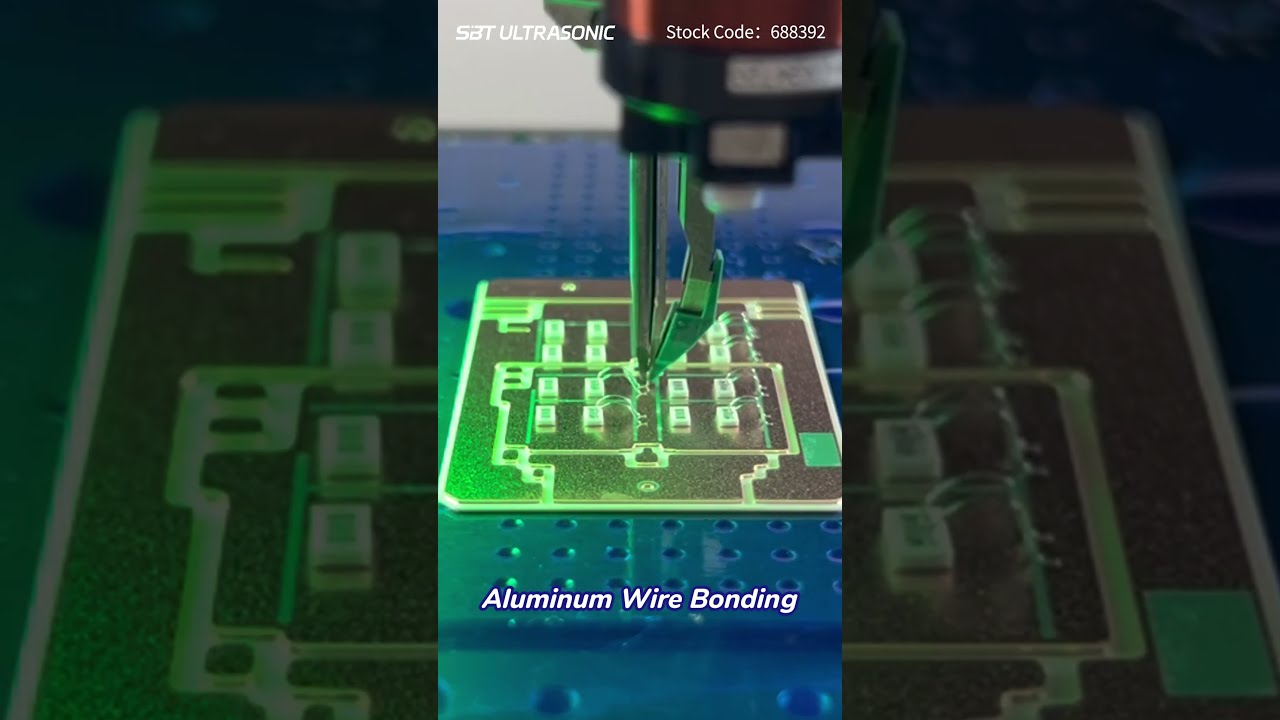

Aluminum Wire Bonding

Aluminum is preferred for its fee-effectiveness and ample electric conductivity yet could require extra protective measures opposed to oxidation.

Copper Wire Bonding

Copper gives finest conductivity at scale down fees however poses demanding situations equivalent to oxidation manipulate for the duration of processing.

Silver Wire Bonding

Silver is much less primarily used yet delivers very good conductivity; nonetheless it, payment concerns traditionally restrict its utility.

Wire Bond Quality Control Measures

Ensuring top first-rate in cord bonding calls for rigorous manipulate measures which includes:

These assessments guide determine capacity defects along with bond lifting or heel cracks which can compromise device overall performance.

Wire Bond Reliability Analysis

Reliability is paramount in determining the fulfillment charge of more than a few cord-bonded applications:

Factors Affecting Reliability

Failure Analysis Techniques

Identifying straight forward failure modes which includes incomplete bonding or contamination enables give a boost to destiny designs through bigger activity controls.

Wire Bond Cost Considerations

Cost diagnosis ought to concentrate on more than a few accessories in contact in twine bonding strategies:

Understanding those factors ensures brands can succeed in gold standard stability among good quality and expenditure.

Applications Across Industries Using Wire Bond Technology

Wire bonding technological know-how unearths vast use throughout several industries:

Wire Bond Applications

Each quarter needs precise traits from cord bonds elegant on operational requisites starting from miniaturization necessities to environmental resilience.

FAQs About Types of Wire Bonding

1. What are the widely used different types of twine bonding?

Answer: The vital versions incorporate Ball Bonning, Wedge Bonning, Ribbon Bonning, and Hybrid Bonning.

2. How does ball bonding differ from wedge bonding?

Answer: Ball bonding forms a small ball on the finish beforehand attaching it while wedge bonding uses a flat instrument with out forming a ball.

3. Why opt aluminum over gold for twine bonds?

Answer: Aluminum tends to be greater expense-powerful than gold whereas offering sufficient conductivity for lots packages.

4. What trying out programs ensure that satisfactory in bonded wires?

Answer: Common checking out ways embrace visual inspections, pull checks, shear tests, and X-ray examinations.

five. How does environmental rigidity influence wire bond reliability?

Answer: Environmental stipulations reminiscent of temperature fluctuations can induce thermal rigidity most suitable to conceivable failures including cracks or detachment through the years.

6 .What industries benefit maximum from complicated twine-bond era?

Answer: Industries inclusive of automotive electronics, aerospace accessories production , clinical devices manufacturing , patron electronics progress , LED production ,and solar mobile phone production broadly receive advantages from those applied sciences .

Conclusion

In conclusion, know-how the more than a few varieties of wire bonding—ball, wedge,ribbon—and hybrid approaches empowers engineers across a number of fields by means of bettering their talent to choose important solutions tailored in opposition to detailed needs even though guaranteeing lengthy-term reliability . The expanding panorama keeps showcasing inventions paving pathways in the direction of more advantageous potency coupled with improved robustness ensuing in the long run fostering development throughout sectors integrating advanced digital systems . With ongoing studies & pattern efforts specializing in refining systems in addition alongside stringent good quality warranty protocols this marketplace will definitely see important improvement traits in advance .

By exploring this manual about Types Of WireBondings :An In-depth Exploration you’re now good-provided draw close foundational ideas riding today's-day electronics!