Wire Bonding Applications: From Semiconductors to Medical Devices

Wire bonding is a fundamental method inside the electronics manufacturing panorama, enjoying an fundamental function in connecting diversified areas inside of semiconductors, medical units, and past. The wire bonding method guarantees that electrical connections are made reliably and correctly. In this newsletter, we will delve into the several factors of wire bonding programs, exploring its approaches, equipment, reliability reasons, and lots greater.

What is Wire Bonding?

Wire bonding is a method used to create electric connections between microelectronic areas. This manner comes to the use of positive wires (characteristically gold, aluminum, copper, or silver) to glue semiconductor chips to their respective substrates or leads. The technique might possibly be done by way of numerous processes adding ball bonding, wedge bonding, and ribbon bonding.

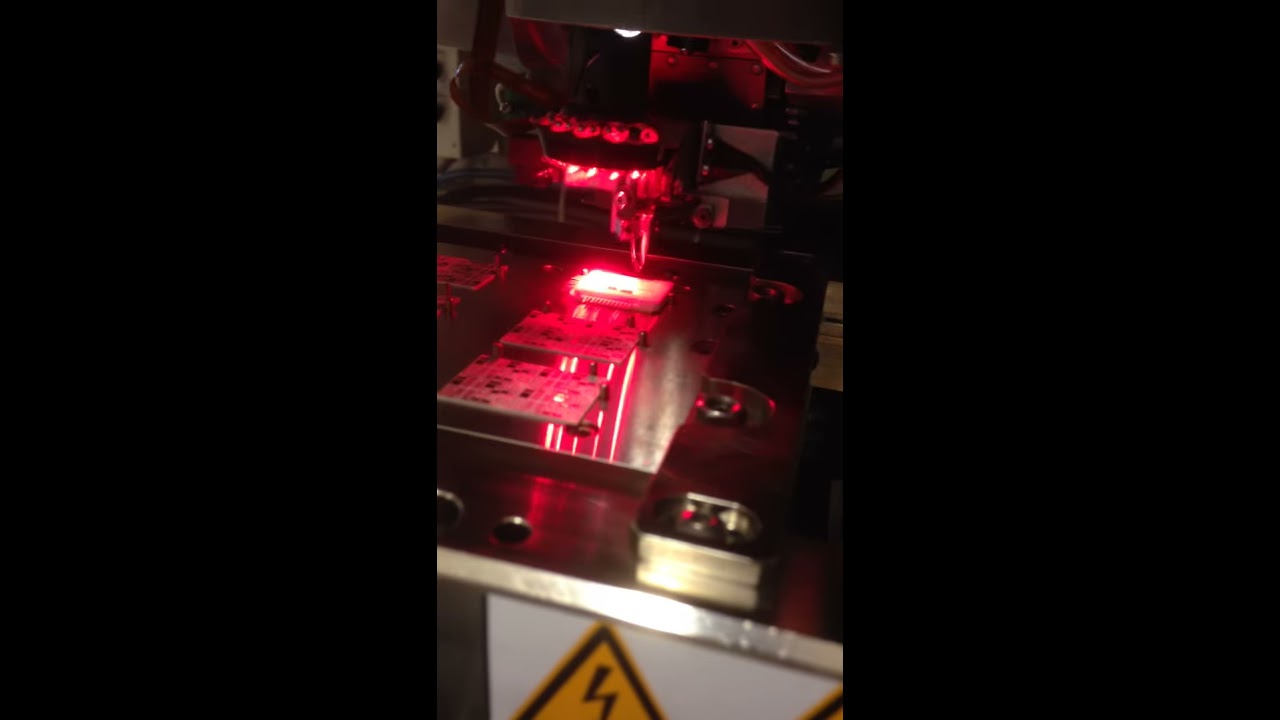

How Does Wire Bonding Work?

The twine bonding process starts with the placement of a tiny wire on a chosen bond pad on a semiconductor die. Using heat and rigidity or ultrasonic vigour, the bond is shaped by melting the interface between the twine and the pad. After securing one end of the twine, it is looped to every other bond pad where it undergoes related medicine.

Table 1: Common Types of Bonding Wires | Type | Material | Applications | |---------------|----------------|--------------------------------------| | Gold Wire | Au | High-frequency applications | | Aluminum Wire | Al | Cost-effectual options | | Copper Wire | Cu | High modern-day purposes | | Silver Wire | Ag | Specialized electronic gadgets |

Wire Bonding Techniques: Overview

There are a few thoughts employed in twine bonding which are chosen dependent on application standards:

Ball Bonding

Ball bonding is characterised by way of forming a small ball on the stop of a wire earlier than creating a connection. This technique is pretty positive for high-frequency units.

Wedge Bonding

In wedge bonding, the bond device uses a flat surface to create bonds. This method helps for larger regulate over bond parameters corresponding to temperature and power.

Ribbon Bonding

This specialised procedure makes use of flat ribbons of steel rather than round wires. Ribbon bonding deals shrink inductance and larger thermal efficiency.

Wire Bonding Equipment: What You Need

To carry out cord bonding properly, distinctive machines and resources are standard:

Wire Bonding Applications: From Semiconductors to Medical Devices

The versatility of cord bonding generation has caused its admired adoption across varied industries:

In Semiconductors

The semiconductor trade heavily is based on cord bonding for interconnecting included circuits (ICs). Its low payment and top reliability make it highest quality for mass creation.

In Medical Devices

Medical expertise calls for utmost precision; subsequently wire bonding plays an mandatory function in connecting sensors and microchips utilized in diagnostic accessories.

Applications in Electronics Manufacturing

- RF modules

- Microcontrollers

- Power electronics

Understanding Wire Bonding Reliability

Reliability in wire bonding refers to the toughness and robustness of bonds below one of a kind situations. Factors influencing reliability comprise:

Common Failure Modes in Wire Bonding

Understanding customary screw ups supports support strategies:

- Bond Lift: A result of insufficient adhesion.

- Heel Crack: Occurs attributable to high rigidity on junctions.

- Oxidation: Degradation due to exposure to air.

Cost Implications of Wire Bonding Technologies

The funding in wire bonding technologies varies extensively headquartered on:

- Machine services (handbook vs utterly automated).

- Material charges (gold vs aluminum).

- Production amount necessities.

Evaluating Wire Bonding Costs

Cost checks need to feel now not basically preliminary investments but additionally long-time period operational costs such as repairs and cloth wastage.

Wire BondingQuality Control Measures in Wire Bonding

Ensuring good quality in the time of creation approaches contains quite a few tactics:

Training Programs for Effective Wire Bonding Execution

To master cord bonding innovations, complete instructions classes are integral:

- Workshops that canopy palms-on event with machine.

- Online lessons concentrating on theoretical skills approximately substances and tools.

Future Trends in Wire Bonding Technology

Emerging traits hint toward recommendations which could adorn performance:

- Integration with Industry 4.0 concepts merchandising automation.

- Development of latest substances reducing quotes when asserting efficiency stages.

FAQs about Wire Bonding

1. What types of bonds are broadly used in cord bonding?

Common kinds encompass gold ball bonds, aluminum wedge bonds, and ribbon bonds suited for one-of-a-kind packages like drive modules or RF circuits.

2. How do I confirm good pleasant management in the course of wire bonding?

Adopt steady inspection practices the use of visual exams and non-adverse checking out approaches like X-ray inspection to track bond integrity continuously.

3. What are a few in style screw ups encountered at some stage in the cord bonding approach?

Common failures comprise bond lift-off by way of insufficient adhesion, heel cracks from extra pressure at junctions, and oxidation from environmental exposure.

4. Is there a really good money difference between gold vs aluminum wire?

Yes! Gold wires commonly rate greater than aluminum yet be offering top-rated conductivity which may possibly justify their use depending on software wishes.

five. How does environmental keep an eye on impact cord bond reliability?

Maintaining superior humidity phases prevents oxidation whereas managed temperatures slash thermal rigidity throughout processing ranges guaranteeing amazing bonds.

6. Are there working towards classes out there for mastering about advanced twine bonding techniques?

Yes! Many institutions present specialized instructions classes ranging from normal tutorials to complicated workshops that specialize in contemporary technologies concerning cord bonding processes.

Conclusion

Wire bonding continues to be a useful generation across a number industries ranging from semiconductors to clinical gadgets caused by its versatility and demonstrated reliability through the years. Understanding its methods—like ball versus wedge as opposed to ribbon—and imposing tremendous first-rate handle measures will make sure that helpful software influence even as minimizing rates related to manufacturing inefficiencies or mess ups down the line!

By staying recommended approximately emerging traits inside this domain—together with Industry 4 .zero developments—brands can additional refine their operations most advantageous in opposition t even more efficiencies relocating ahead!