November 22, 2023

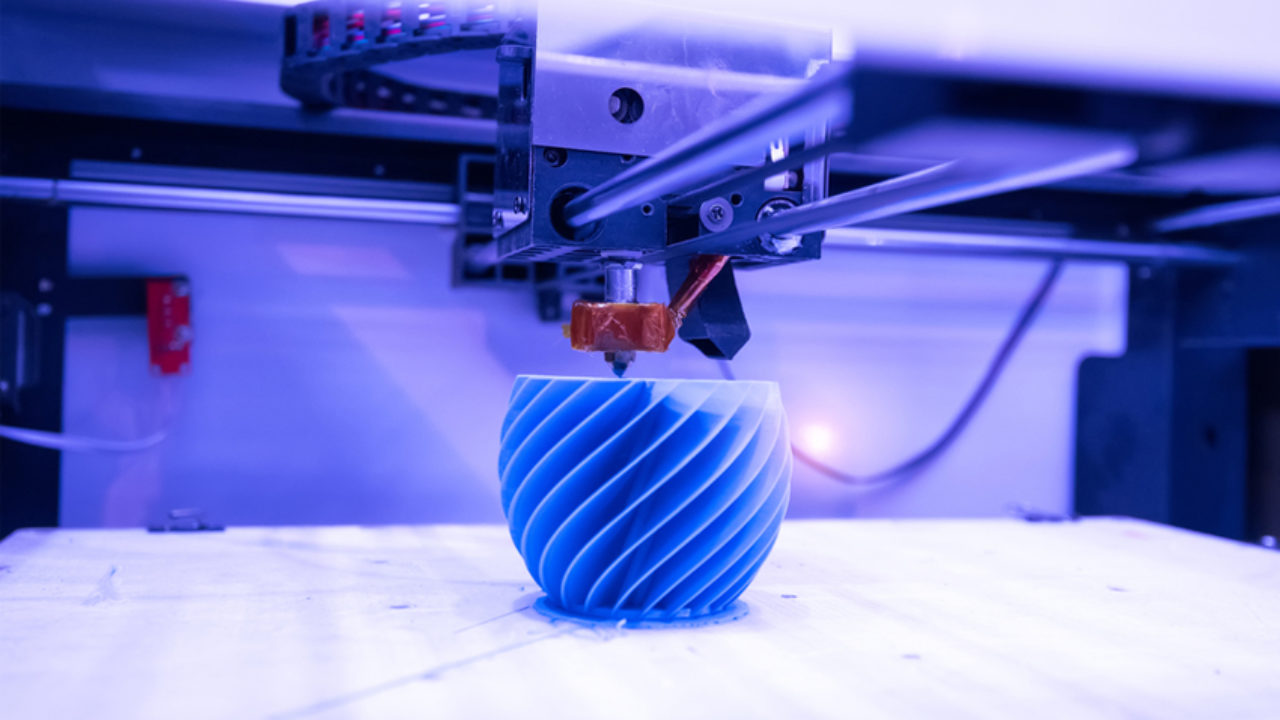

New 3d Printing Process Is Much Faster And Also Much More Exact Than Conventional Techniques Sciencedaily

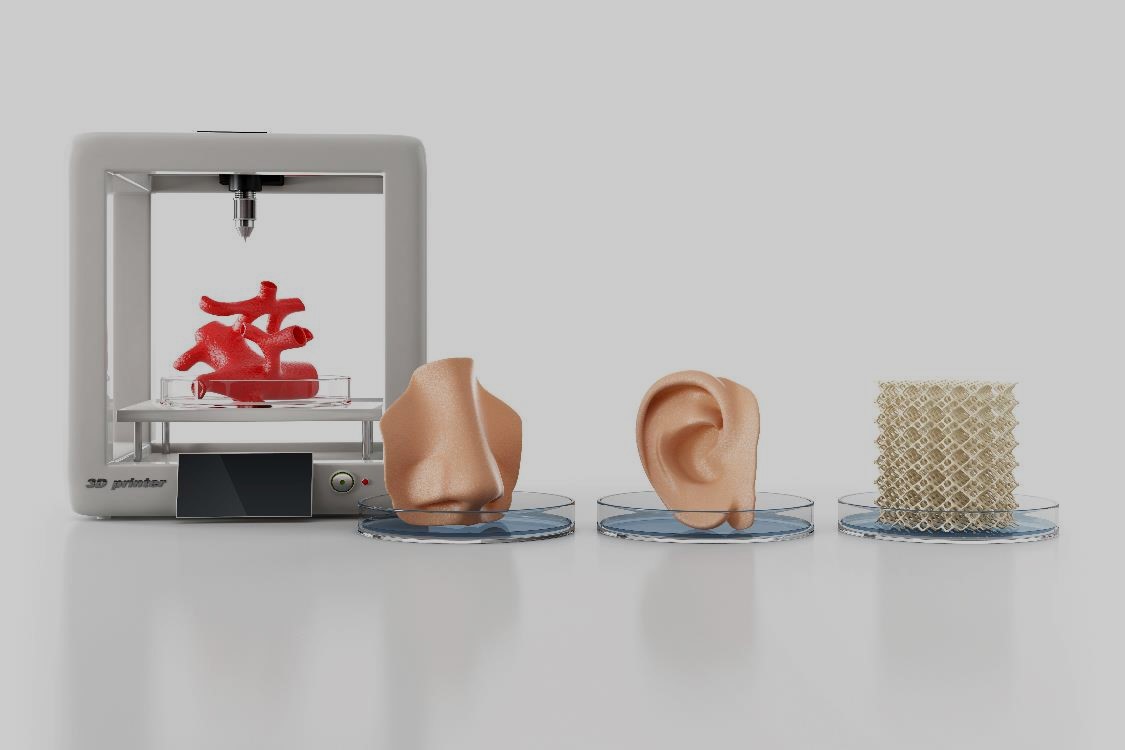

New 3d Printing Technique For Manufacturing Ultrasmall Metallic Objects Like various other 3D printers they consist of a print nozzle, tubes for feeding in the print product, a control device and the mechanical elements for moving the nozzle-- yet in these printers everything is a little smaller sized than common. Moreover, any type of tech lover will certainly be able to notify you regarding the convenience with which it allows the creation of extremely advanced parts with little to no waste. Moreover, all the readily available 3D printing methods manage to offer the comfort of very easy and also reliable changes while lowering both your price and also time. Today, different 3D printing methods are important for several commercial industries.4D Printing Market Projected to Experience Remarkable Growth ... - Digital Journal

4D Printing Market Projected to Experience Remarkable Growth ....

Posted: Thu, 08 Jun 2023 02:19:17 GMT [source]

Clinical Xpress

It is necessary to carefully monitor the component throughout the process, occasionally checking the progression as well as removing the component from the container once the wanted surface has been accomplished. When the component is gotten rid of, it must be permitted to air dry to evaporate any type of continuing to be solvent and to strengthen the softened external layer. Polymer paints are water-based, making them easy to deal with and also tidy up, while giving a wide range of colors and coatings. Enamel paints, on the various other hand, are solvent-based and offer a more long lasting and glossy coating. Spray paints can be made use of for a quick and also application, however they call for correct air flow as well as security precautions, such as wearing a respirator as well as protective clothing. That stated, I've currently adopted strategies that essentially remove this issue in my jobs.PAINTing a wound-healing ink into cuts with a 3D-printing pen - Science Daily

PAINTing a wound-healing ink into cuts with a 3D-printing pen.

Posted: Thu, 01 Jun 2023 15:33:45 GMT [source]

-- Product Extrusion

It enables publishing multi-color objects, water soluble assistances, or get rid of various product buildings. Dual extrusion calls for a 3D printer with 2 extruders and compatible cutting software program. Liao HT, Lee MY, Tsai WW, Wang HC, Lu WC. Osteogenesis of adipose‐derived stem cells on polycaprolactone-- β‐tricalcium phosphate scaffold fabricated using discerning laser sintering as well as surface finish with collagen kind I. This is a moving border diffusion-reaction issue that also without biodegradable biomaterials can cause hypoxia and also acidosis within the scaffolds. The launch of acidic destruction items is anticipated to worsen the acidosis which might harm the seeded cells and/or the surrounding cells".What is the strongest 3D printing approach?

Polycarbonate. According to several manufacturers as well as reviewers, polycarbonate (PC) is considered the strongest customer filament available. Computer can yield incredibly high-strength components when printed appropriately with an all-metal hot end and also an unit.

- The assimilation of SFF technologies with patient-specific medical imaging data makes it possible for the aseptic manufacturing of cells engineering grafts that match exactly to a client's contours can be created by.

- It is basically mould-free shot molding of last structures, making it possible to produce distinctive, one person at once clinical gadget.

- However when those obstacles are overcome-- or alleviated-- rate of interest in various 3D printing materials is high.

- Additive manufacturing units construct any type of component one layer at a time and bring a lengthy checklist of advantages to the table.

Social Links