November 22, 2023

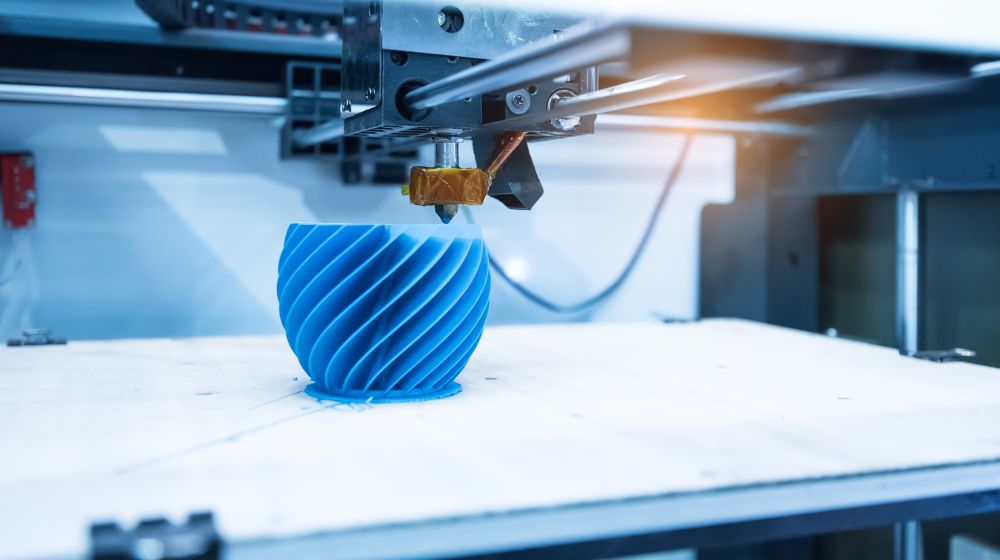

Troubleshooting & Supplies 3d Printing Additive Manufacturing Sbu Collections At Southwest Baptist University Libraries

Print Troubleshooting Pictorial Overview Generally, the primary reason is that the print is unable to bond.There requires to be a base with an appearance on your system. So to fix this you will certainly require to improve the bonding buildings of the surface. In many cases the trouble hinges on either the nozzle or filament supply. In some cases the factor is trivial-- for instance, a filament runout. It can be simply hard to notice if the filament spool is concealed. Or the idler tension is excessively tight, which could cause the filament being stripped as well as stagnating through your printer. This is a typical mistake and there are lots of reasons for gaps in your print, depending on where they lie. It's worth checking whatever stated in this section so that you don't miss the specific reason. Most likely, the 3D printing surface area of that layer is over-extruded which's why the nozzle scratched it in the step. The balls are usually an outcome of the retraction that is taking place at those factors.Inconsistent Extrusion: Exactly How To Repair Over Extrusion

The issue could materialize itself with various severity during the printing procedure. If you squeeze two belts together, a minor resistance needs to be really felt. If the belt's top section is tighter than the lower one, after that it needs changing and tightening.What are the typical 3D printing troubleshooting troubles?

- Not Squeezing out at Start of Publish. Printer does not extrude plastic at the beginning of the print.Not Sticking to the Bed.Under-Extrusion. Over-Extrusion.

- Spaces in Top Layers.Stringing or Oozing.Overheating.Layer Shifting. Dimension.

- One feature to think about when

- producing your item is it's scale.The resolution.

- Throughout additive manufacturing, the resolution refers to the thickness of each layer of product being'applied.Wall thickness.The orientation.The choice of

- material.Design balance. When a PLA filament takes in moisture, it inflates, raising the risk of extruder jams. Dampness likewise triggers PLA to produce prints with bubbles and also gaps externally, as a result spoiling your prints

- .

Openings And Also Pits In Top Layer

After this, the print head adheres to the Z-axis, lifts and also goes back to the beginning point to provide the next layer. One more particular method to avoid buzzing is firmware velocity. Experienced individuals need to be familiar with Acceleration and also Jerk-- these setups allow you tailor the speed of the head when transforming instructions during the manufacturing.- Fortunately MyMiniFactory brag assured data, so this is usually a great area to begin.

- Do so for a minimum of all 4 corners, then check the center of the bed.

- Filaments are referred to as thermoplastics as well as when they cool, they can diminish when cooling down as well quickly.

- Every appropriate slicer out there has the option to define a various print speed for your very first layer.

3D Printing News Briefs, March 30, 2023: Rubber 3D Printing Service, Titanium Powder, & More - 3DPrint.com

3D Printing News Briefs, March 30, 2023: Rubber 3D Printing Service, Titanium Powder, & More.

Posted: Thu, 30 Mar 2023 07:00:00 GMT [source]

Social Links