November 7, 2023

Just How To Make Solid 3d Prints: 5 Pointers To Strengthen 3d Printed Parts

Publishing Tips Archives Stldenise3d 3D printing needs a mutual understanding of spatial relationships, as trainees need to have the ability to visualize exactly how their style will search in 3D This can help boost spatial reasoning skills, which can equate to better efficiency in math and also scientific research. 3D printers can help bring STEM based on life by permitting pupils to visualize complex ideas in a concrete way. This can help raise involvement and also passion in scientific research, innovation, design, as well as mathematics, and also can also help connect the gender space in these areas. When thinking about the cost and advantages of the recommended 3D printers, the FlashForge Finder sticks out as one of the most cost-effective choice. It has a budget friendly cost, is easy to use, and also has a camera to keep track of printing.How to get into 3D printing without breaking (too many) things - ZDNet

How to get into 3D printing without breaking (too many) things.

Posted: Sat, 04 Mar 2023 08:00:00 GMT [source]

High-speed Printing With Fiberlogy Easy-petg

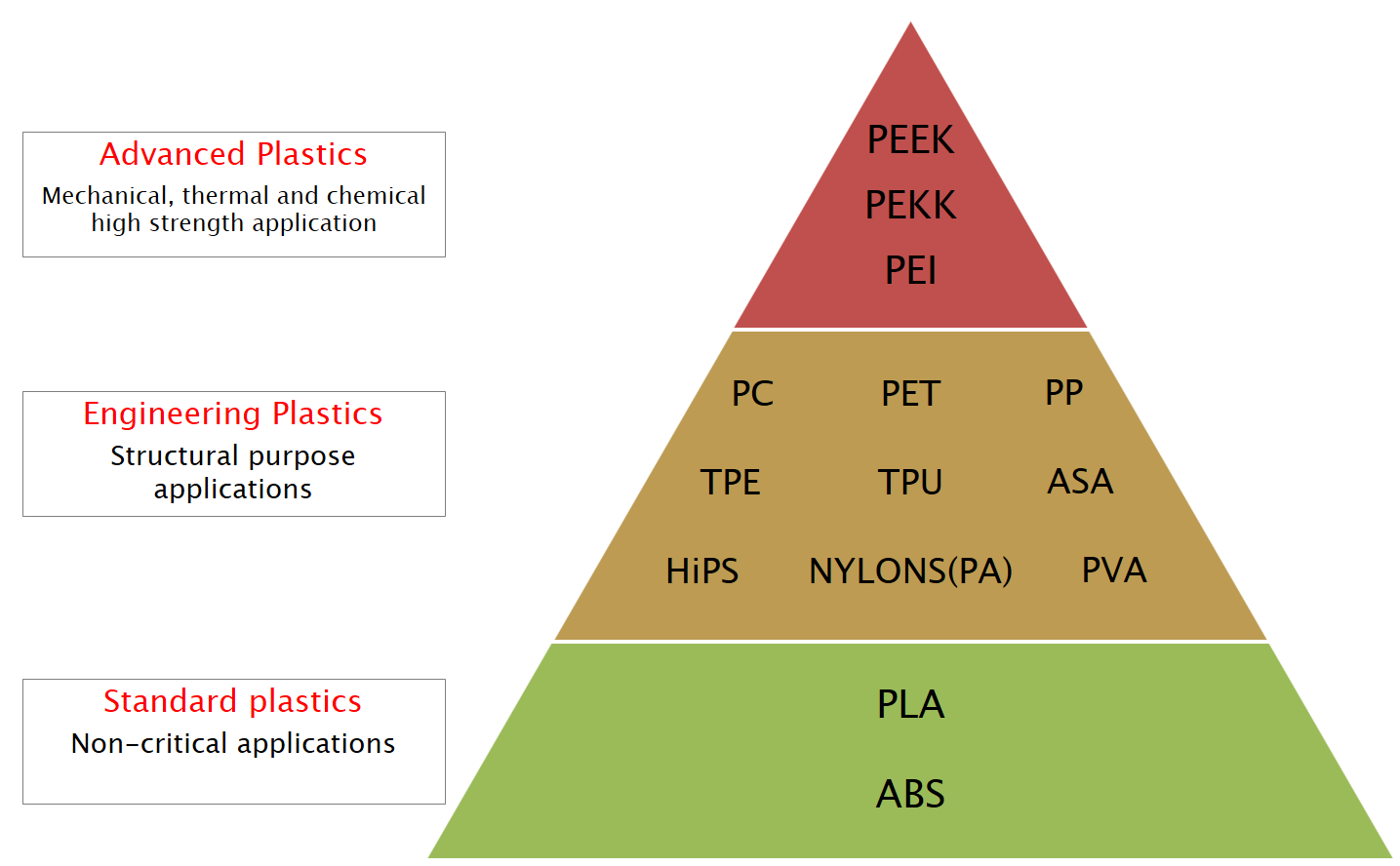

There are three significant products with residential properties associated with toughness. They have actually tessellated hexagons and the highest toughness to weight proportion. Unlike the previous 2 infill patterns, printing is sluggish because of the printhead regularly altering instructions, yet they are also efficient in enhancing 3D prints.The SMuFF Multi-Material Extruder: A Closer Look - All3DP

The SMuFF Multi-Material Extruder: A Closer Look.

Posted: Thu, 29 Sep 2022 07:00:00 GMT [source]

Lower Cooling

Nonetheless, you may have to await a long period of time to see your task. That's where resonance settlement formulas step in. A technique pertaining to the layer size is choosing a broader nozzle. Borders are similar to skirts, yet the attachment assistance has a broader base Click here to find out more and also it really holds back the sides of your part.Why are my 3D prints so bad?

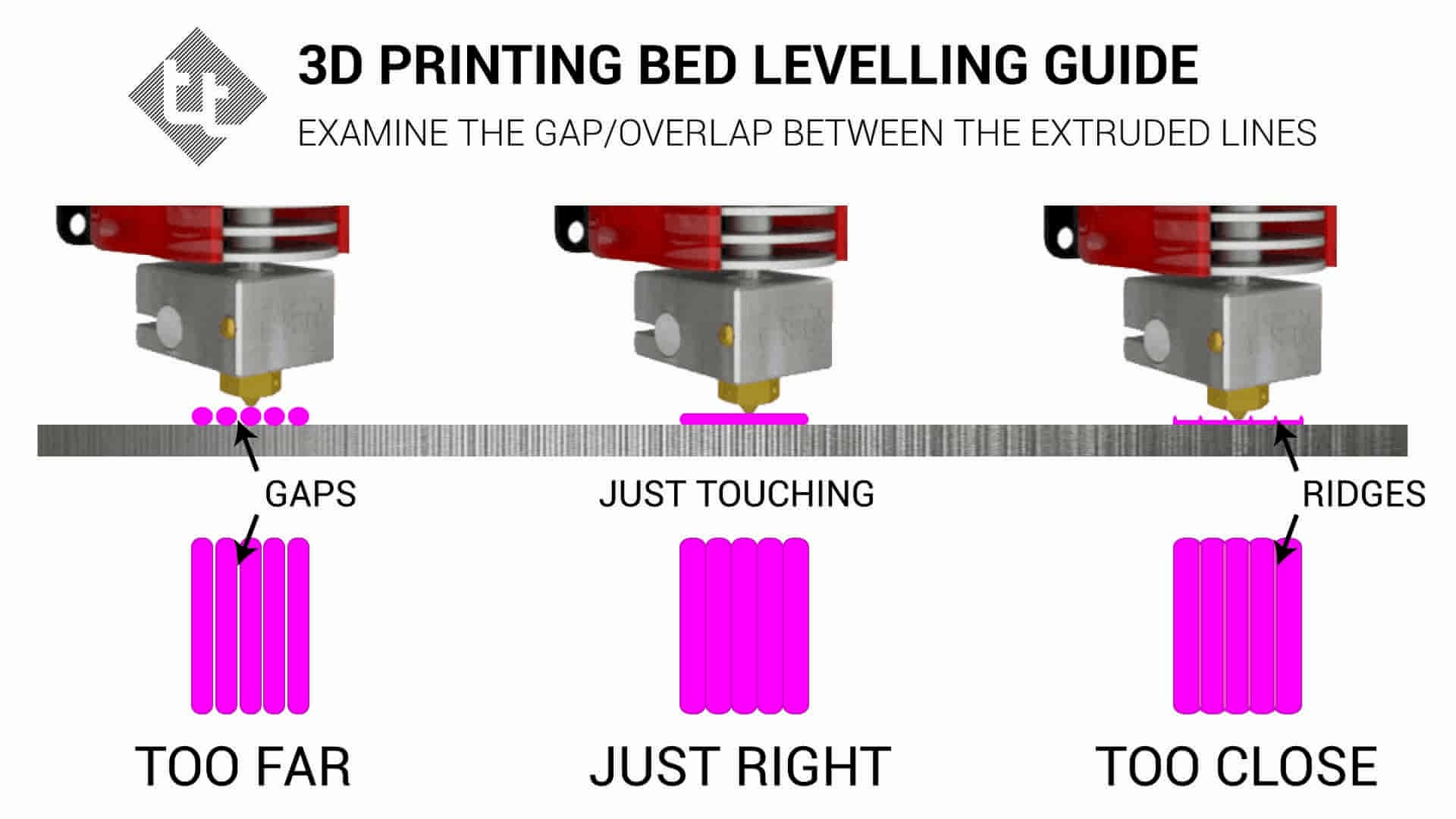

One of the most usual reason is merely that the print simply doesn't bond to the surface of the print platform. The filament needs a textured base in order to adhere, so to address the issue you''ll require to produce a much better bonding surface. An unlevel print platform can be one more major concern.

Tips For Incorporating 3d Printing Into The Educational Program Of Primary Schools

You can make modifications while the 3D printer is printing to tweak your first layer. On some printers, Z0 may be also much from the bed, even when all the screws are loose. In that case, you'll need to move the Z-minimum endstop slightly reduced to calibrate. A collection where we will certainly be discussing methods and tactics to get that excellent print. This series is made for newbies and eventually progressed individuals so we'll be beginning with basics and also going up into advanced methods as time takes place. For instance, after adjusting Linear Development you will be able to get cleaner and sharper sides for designs, even more even extrusion throughout printing and also lower retraction values.- So I bought some clear decal sheets that I could run through my inkjet printer.

- Skirts are the easiest as well as fastest to publish, however despite their name, they do not in fact use any kind of assistance whatsoever.

- Art knives are various other sharp devices that are simple to be careless with when you're trying to tidy up finished 3D prints, just be conscious around sharp devices for your safety and security.

- Look into the video below for a wonderful visual about 3D printing at different layer elevations.

- In the image below, you can see the result I am speaking about.

Social Links