November 22, 2023

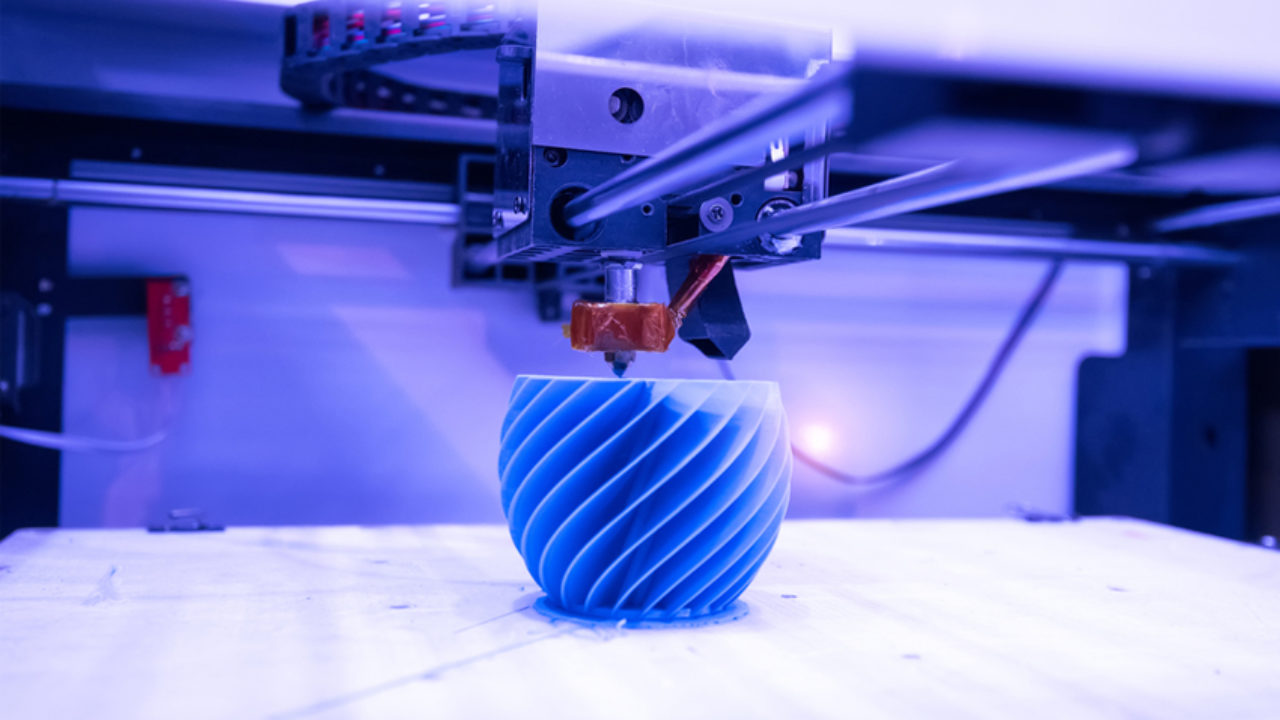

Just How To Make Strong 3d Prints: 5 Suggestions To Strengthen 3d Printed Parts

Leading Ten Ideas When Getting Started With 3d Printing By making certain a level bed, optimal temperature levels, slower speeds, and also proper bed preparation, you can prepare for a remarkable 3D print. For more insights on fixing typical 3D printing issues, don't neglect to look into our comprehensive Publish Top quality Guide. The 2nd thing to bear in mind when developing a component to be 3D printed is wall surface thickness. Every 3D printing procedure has its very own level of precision. You can comply with the retraction calibration procedure Helpful site I shared, to generate a calibration tower as well as discover the best value for your printer. However do it just after you find the very best temperature for your filament. Besides the belt tightening concern, this kind of VFA result on the external walls can show up due to micro tipping concerns as well as stepper electric motors which don't move evenly. As a suggestion, I advise you do the Z countered calibration with your nozzle as well as bed heated to the very same temperatures as when you leveled your bed. A bed probe can aid if you have an uneven print surface area, and make up for the small variations on your bed, but it can not magically repair your problems. It is easy to use, very easy to set up, as well as has a huge develop quantity. However, its high rate may not appropriate for schools with strict spending plans. In my earlier, merely electronic globe, I developed my art on the screen. And I additionally have the product I require to print them with. These are Home Depot or BJ purchases, and also they are wonderfull. I have one cart for printing product, and also one cart for published things and also paint.For Friday: Start With Power Effectiveness, An Approach For Cybersecurity And Also A Study About Technology Needs

As an example, the PEI construct surface flaunts the advantage of very easy print removal and also does not necessitate the use of bed adhesives like adhesive. You can customize your 3D printer with a PEI print bed to make publishing a lot simpler. Each 3D printer filament features a manufacturer-recommended temperature level range in which the filament does the very best.- They consist of a network of supportive frameworks and sticking out items that help a body keep its form without needing to print a solid structure.

- Or you could see some under extruded sections in your infill.

- Doing so can offer you the best chances of success as PLA is less prone to cracking when a print expands, unlike abdominal muscle.

- So, the 3D printer needs to be as stable as feasible with no resonances for the best high quality prints.

Utilize A Solid Infill Pattern

Relying on the specifications set up, the faceting of the 3D design will certainly differ. Typical specifications that impact faceting of STL data consist of chord height, variance, angle resistance as well as poly count. It's critical to prepare your declare the export with this in mind to ensure top quality expectations as well as layout intents are kept from CAD to last part manufacturing. Even an inexpensive FDM 3D printer for beginners lets you build a stunning porcelain figurine right at your house. Yet it would disturb anybody to experience 3D printing issues.3D Printing & Safety: All You Need to Know to Print Safely - All3DP

3D Printing & Safety: All You Need to Know to Print Safely.

Posted: Mon, 26 Dec 2022 08:00:00 GMT [source]

Steel 3d Printer Printers

Similar to PEI, other bed surfaces have their own benefits and drawbacks that may or might not suit your choices. I assemble a total overview called Just how to Adjust Your 3D Printer. You can download and install the XYZ Calibration Dice on Thingiverse. Once you print the design, you want to determine the cube with a set of digital calipers as well as attempt to obtain a value of 20mm for every dimension.Just how can I make my 3D prints much better high quality?

Social Links